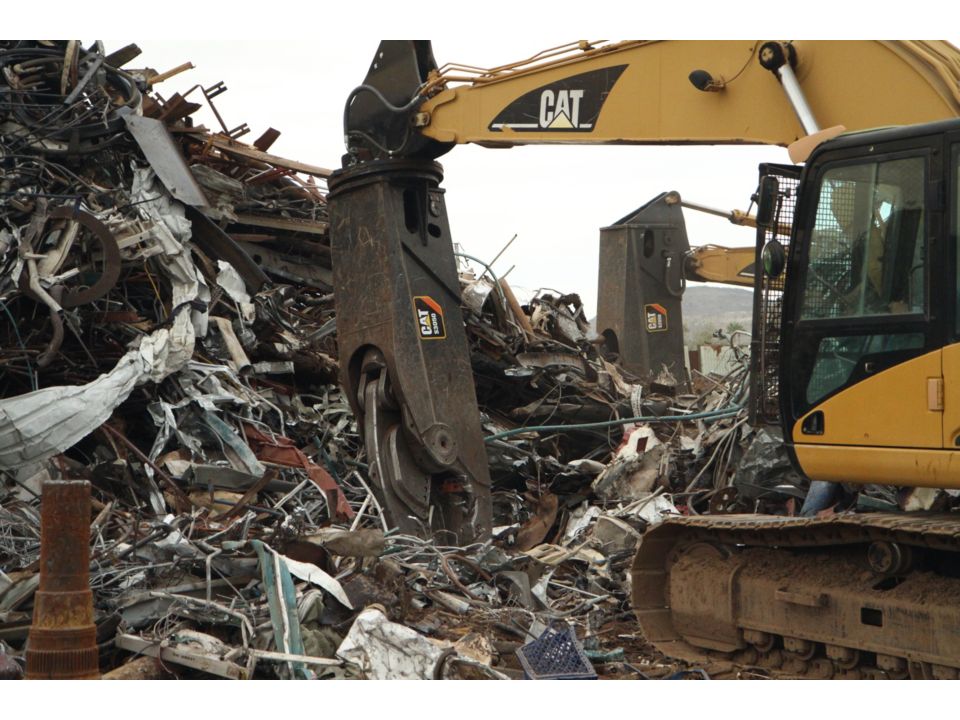

S3015 Rotating Scrap & Demolition Shear

S3015 Rotating Scrap & Demolition Shear

Book a Demo

Explore my deals

-

Weight - Boom Mount3331 lb 1511 kg

-

Weight - Stick Mount3234 lb 1467 kg

-

Length105 in 2677 mm

-

Height36.2 in 920 mm

-

Width25.2 in 640 mm

-

Jaw Width - Fixed12 in 304 mm

-

Jaw Width - Moving3.9 in 100 mm

-

Jaw Opening15.7 in 400 mm

-

Jaw Depth15 in 380 mm

-

Throat Force273 ton-f 2425 kN

-

Apex Force130 ton-f 1155 kN

-

Tip Force69 ton-f 618 kN

-

Cutting Circuit - Maximum Relief Pressure5075 psi 35000 kPa

-

Cutting Circuit - Maximum Flow33 gpm 125 L/min

-

Rotation Circuit - Maximum Relief Pressure2030 psi 14000 kPa

-

Rotation Circuit - Maximum Flow11 gpm 40 L/min

-

Stick Mounted - Minimum12 tons

-

Stick Mounted - Maximum18 tons

-

Boom Mounted - Maximum10 tons

-

Boom Mounted - Minimum7 tons

-

Cycle Time - Close2 Seconds

Cut More, Cut Faster

- More productive by design. Shears are designed as a system solution to cut more tons per day and make you more money by balancing machine capabilities, shear cylinder size, jaw depth and opening, and leveler arm length.

- Increase cut efficiency by up to 15 percent and reduce blade wear with the dual offset apex jaw design.

- Accurately place the jaws in optimum cutting position without moving the machine with the standard 360° rotator on the S3000 Series.

- Power is consistent through the entire cutting cycle.

- The shears are optimized for Cat excavators to ensure proper matching, optimal cycle times, and range of motion.

- Increase cutting efficiency with tapered spacer plates which reduce jamming and drag.

- The cylinder rod is completely protected inside the frame reducing downtime and the risk of damage and allowing for a slimmer design for better visibility.

- The jaw relief area allows material to fall away freely without hindering the next cutting cycle.

Long-Lasting Quality

- Reduce maintenance costs with the new Bolt-on Piercing Tip. Dowels protect the bolts from stress that leads to loosening and a bushing equalizes force on both halves of the tip to help prevent splitting.

- Work confidently with demanding hydraulic requirements. Major hydraulic components are built with a 4 to 1 safety factor and can withstand pressure spikes up to 20,000-psi (1378 bar).

- Increase overall durability with the solid plate construction of the upper jaw.

- The housing is designed with a 60 percent safety factor in yield strength and high-stress areas are built with extra thick plates.

- The heel plate is constructed of AR400 high-wear resistant material to provide long life between weld build up and replacement.

- Endure high forces with confidence with the oversized torque tube.

Easy to Maintain

- Easily and safely complete maintenance tasks. Shears can be greased at ground level along with the machine stick cylinder pin and boom pin.

- Reduce downtime with field serviceable swivels. Removing and resealing can be done quickly and easily while the shear is mounted to the machine, without the need to take it to a shop.

- Service and adjust the pivot group without the need for any special tools. The side play can be easily adjusted by simply tightening the pin.

- Easily change the tip and flip the blade in thirty minutes with standard tools.

- Access the cylinder’s hoses and speed valve easily from the side of the shear. This feature eliminates the need for a cover that can fall off and need repaired.

- You are supported. The Cat Dealer Network is your one point of contact for all your service needs.

Options to Meet Your Needs

- Connecting your shear to a variety of machines has never been easier. Dual high-pressure ports allow the shear to attach to any compatible machine regardless of the hydraulic layout.

- Meet your specific needs with straight and rotating configurations and boom and stick mount options.

- Straight – S2000 Series

- Boom mounted

- Used in secondary demolition and scrap applications

- Rotator is eliminated, reducing maintenance costs

- Larger shears can be used on smaller machine size classes

- Rotating – S3000 Series

- Boom or Stick mounted

- Used in scrap, primary, and secondary demolition applications

- Provides optimal cycle times and positioning

- Boom Mounted – Ideal for scrap applications, boom mounted shears allow for easier handling and operation.

- Stick Mounted – Ideal for demolition applications, stick mounted shears are compatible with larger machines and provide a greater reach.

- Straight – S2000 Series

The Toromont Cat advantage

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed eros justo, volutpat sed sem vel, tincidunt dictum ex. Curabitur eget massa nec enim viverra fermentum vel eu ligula.

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed eros justo, volutpat sed sem vel, tincidunt dictum ex.

Contact an equipment specialist

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed eros justo, volutpat sed sem vel, tincidunt dictum ex. Curabitur eget massa nec enim viverra fermentum vel eu ligula.