920

-

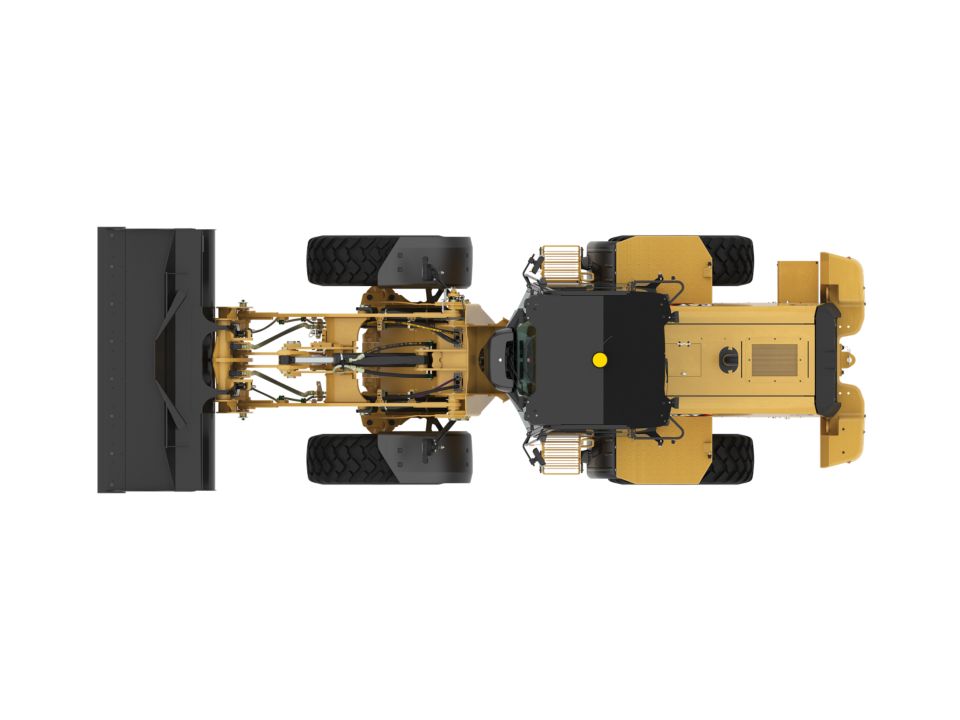

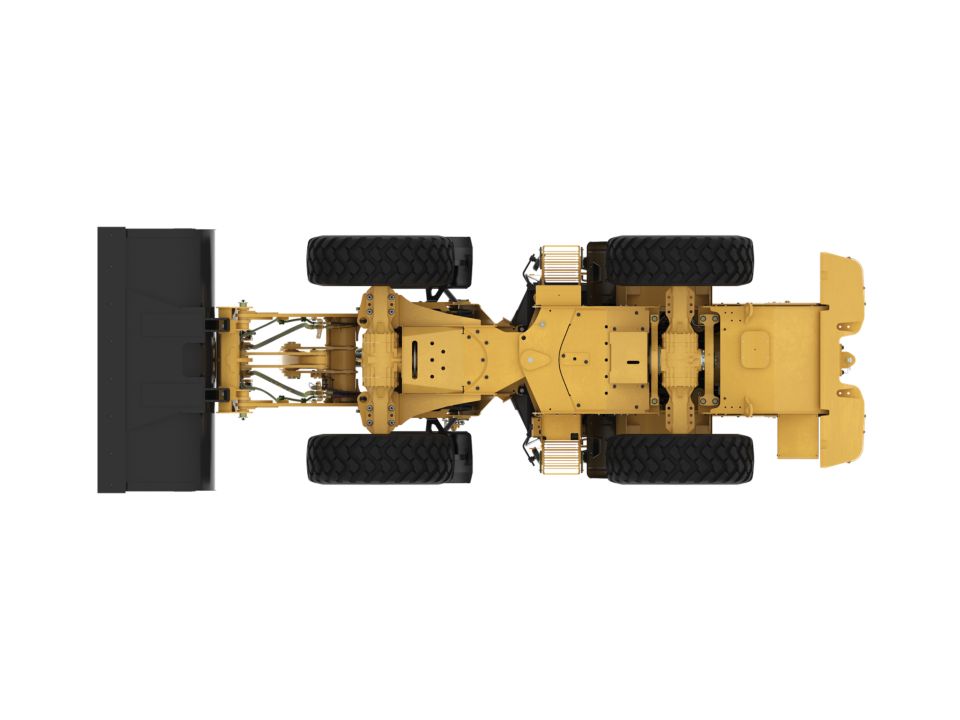

RearOscillating ±11 degrees; Locking differential (standard)

-

FrontFixed; Locking differential (standard)

-

Bucket Capacities1.3-3.5 m3 (1.7-4.6 yd3)

-

Bucket Capacities - General Purpose1.3-1.9 m³ (1.7-2.5 yd³)

-

Bucket Capacities - Light Material2.5-3.5 m³ (3.3-4.6 yd³)

-

ROPSISO 3471:2008

-

FOPSISO 3449:2005

-

Note (3)The labelled sound power level for the CE marked configurations when measured according to the test procedure and conditions specified in 2000/14/EC (as amended by 2005/88/EC) is 103 dB(A).

-

Note (2)The declared dynamic operator sound pressure levels per ISO 6396:2008*, when the cab is properly installed and maintained, is 77 dB(A).

-

Note (1)Cab and Rollover Protective Structures (ROPS) are standard in North America and Europe.

-

Note (4)*The measurements were conducted with the cab doors and windows closed.

-

Maximum Gross Power121 hp 90 kW

-

Rated Net Power - Rated Engine Speed2200 r/min 2200 r/min

-

Maximum Gross Power - Rated Engine Speed2200 r/min 2200 r/min

-

Rated Net Power - SAE J1349120 hp 90 kW

-

Maximum Gross Power - ISO 14396 (metric)122 hp 122 hp

-

Rated Net Power - ISO 9249118 hp 88 kW

-

Maximum Gross Torque - SAE J1995372 ft·lbf 505 N·m

-

Maximum Gross Torque - ISO 14396369 ft·lbf 500 N·m

-

Maximum Net Torque - SAE J1349366 ft·lbf 496 N·m

-

Maximum Net Torque - ISO 9249363 ft·lbf 493 N·m

-

Displacement220 in³ 3.6 l

-

Bore3.85 in 98 mm

-

Stroke4.72 in 120 mm

-

Engine ModelCat C3.6

-

EmissionsEngine meets Tier 4 Final/Stage V emission standards.

-

NoteNet power advertised is the power available at the flywheel plus front drive implement pump when the engine is equipped with fan, air cleaner, muffler and alternator.

-

Maximum Gross Power - ISO 14396121 hp 90 kW

-

Relief Pressure - Tilt Cylinder4641 psi 32000 kPa

-

Maximum Flow - Implement Pump - 3rd Function, Maximum Flow, Standard25 gpm 95 L/min

-

Maximum Flow - Implement Pump43.6 gpm 165 L/min

-

Relief Pressure - Tilt Cylinder - 4th Function Relief Pressure4641 psi 32000 kPa

-

Hydraulic Cycle Time - Float Down, Maximum Lift to Ground Level2.7 s 2.7 s

-

NoteAll cycle times listed are with cylinder snubbing turned off.

-

Maximum Working Pressure - Implement Pump4061 psi 28000 kPa

-

Hydraulic Cycle Time - Total Cycle Time11.5 s 11.5 s

-

Hydraulic Cycle Time - Rackback2.2 s 2.2 s

-

Maximum Flow - Implement Pump - 4rd Function, Maximum Flow25 gpm 95 L/min

-

Hydraulic Cycle Time - Dump, at Maximum Reach1.8 s 1.8 s

-

Hydraulic Cycle Time - Raise, Ground Level to Maximum Lift4.8 s 4.8 s

-

Maximum Flow - Implement Pump - 3rd Function, Maximum Flow, High40 gpm 150 L/min

-

Transmission0.8 gal (US) 3.2 l

-

Engine Crankcase2.6 gal (US) 10 l

-

Diesel Exhaust Fluid (DEF) Tank4.8 gal (US) 18 l

-

Axles - Rear4.5 gal (US) 17 l

-

Cooling System5.7 gal (US) 21.5 l

-

Hydraulic System - Including Tank25.9 gal (US) 98 l

-

Axles - Front4.5 gal (US) 17 l

-

Fuel Tank43.6 gal (US) 165 l

-

Hydraulic Tank14.5 gal (US) 55 l

-

NoteDEF used in Cat Selective Catalyst Reduction (SCR) systems must meet the requirements outlined in the International Organization for Standardization (ISO) standard 22241-1.

-

Maximum Working Pressure - Steering Pump3190 psi 22000 kPa

-

Steering Cycle Times - Full Left to Full Right - At 2,350 rpm: 90 rpm Steering Wheel Speed2.3 s 2.3 s

-

Steering Articulation Angle - Each Direction40 ° 40 °

-

Number of Steering Wheel Turns - Full Left to Full Right or Full Right to Full Left3.4 turns 3.4 turns

-

Maximum Flow - Steering Pump21.7 gpm 82 L/min

-

Recyclability95%

-

Other Choices Include17.5 R25 L3 XHA2; 20.5 R25 L3 XHA3; 17.5-25 L2/L3 SGL; 20.5-25 L2/L3 SGL; 17.5-25 L3 HRL D/L-3A; 17.5 R25 L2 Snow; 20.5 R25 L2 Snow; 17.5 R25 Solid

-

Standard Size17.5 R25 L2 XTLA

-

Note (1)Other tire choices are available. Contact your Cat dealer for details.

-

Note (3)Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model.

-

Note (2)In certain applications, the loader’s productive capabilities may exceed the tire’s tonnes-km/h (ton-mph) capabilities.

-

Note*Creeper Control allows speed control from a stand still up to 10 km/h (6.3 mph). The Creeper Control will only work in Range 1.

-

Forward and Reverse - Speed Range 325 mile/h 40 km/h

-

Forward and Reverse - Speed Range 2*12.5 mile/h 20 km/h

-

Forward and Reverse - Speed Range 1*6.3 mile/h 10 km/h

-

Operating Weight21742 lb 9865 kg

Cat® C3.6 Engine

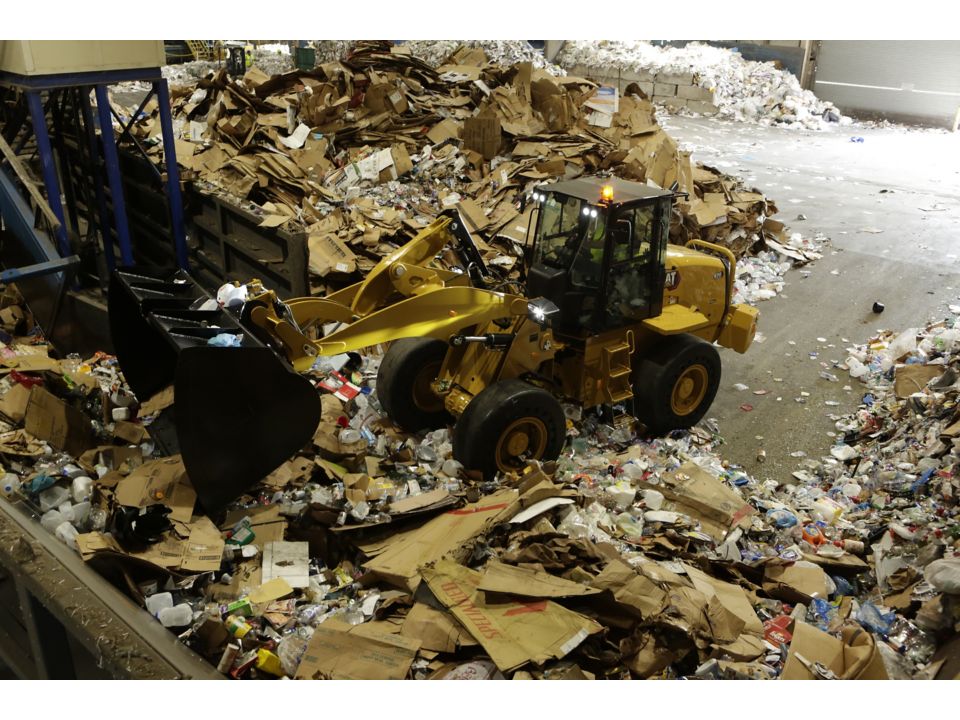

Cat Optimized Z-bar Loader Linkage

Work Tools

Hydraulics and Controls

Tuned Drivetrain

Cab

Serviceability

Efficiently Powerful

Standard Fuel Savings Features

Sustainability

- The Cat® C3.6 engine meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

- Engine Idle Shutdown Timer reduces fuel burn, greenhouse gas emissions and unnecessary idle time by shutting down the machine after a pre-set idling period.

- Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency by allowing your Cat dealer to virtually test the machine while working. Once a problem is identified, a technician can fix it the first time, saving time and money.

- Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

- Advanced Electro Hydraulic System provides the optimum balance of power and efficiency while giving you the control you need for your precise jobsite requirements.

- Engine Demand Fan is hydraulically driven to provide machine cooling only when needed, improving fuel efficiency and reducing greenhouse gas emissions.

- Hydrostatic Transmission is an efficient way to transfer engine power to the wheels at low speeds versus a torque converter.

- Performance Series Buckets have rounded side boards, a longer floor and open angle to carry more and load quicker so each pass is the most efficient.

- Rimpull Control is a quick way to adjust the torque to the tires for less slipping and tire wear.

- Match the wheel loader to the job using power modes including Eco Mode that reduces engine speed and hydraulic power for applications not requiring full hydraulic power - helping you to reduce fuel consumption and greenhouse gas emissions.

- Programmable sensors and kickouts help you work quicker and more comfortable reducing wear on machine and the attachment

The Toromont Cat advantage

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed eros justo, volutpat sed sem vel, tincidunt dictum ex. Curabitur eget massa nec enim viverra fermentum vel eu ligula.

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed eros justo, volutpat sed sem vel, tincidunt dictum ex.

Contact an equipment specialist

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed eros justo, volutpat sed sem vel, tincidunt dictum ex. Curabitur eget massa nec enim viverra fermentum vel eu ligula.