270

270

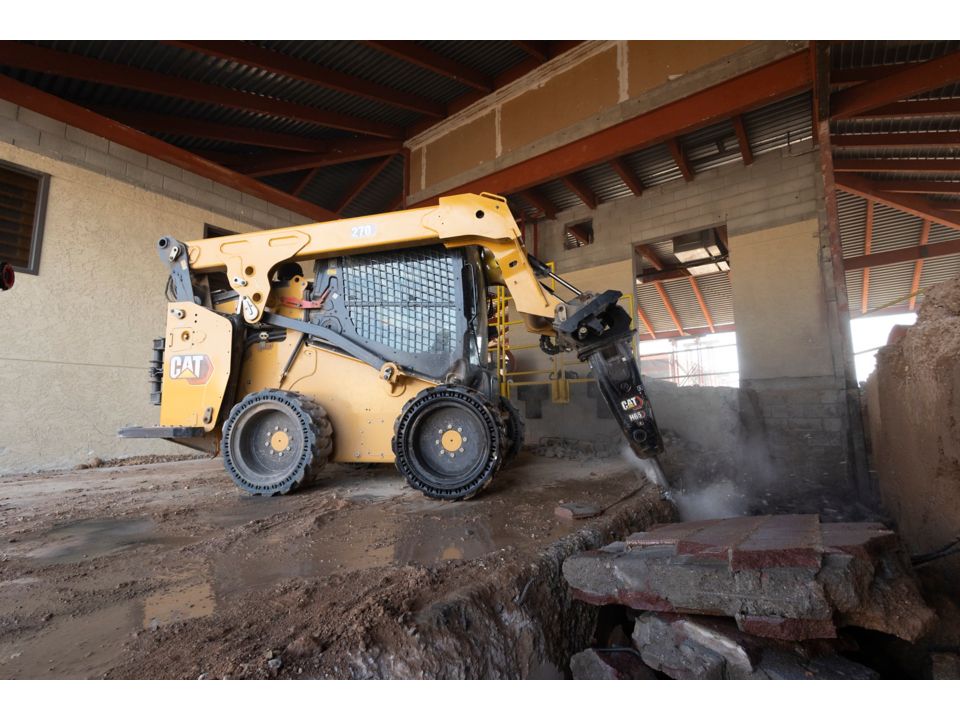

Built for tough work, the Cat® Skid Steer Loaders incorporate big iron features. These machines deliver reliability, durability, and efficient operation, even in the toughest working conditions.

Book a Demo

Explore my deals

Specifications

Air Conditioning System (if equipped)

-

Air ConditioningThe air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 0.85 kg of refrigerant which has a CO2 equivalent of 1.216 metric tonnes.

Cab

-

ROPSISO 3471:2008

-

FOPSISO 3449:2005 Level I

-

FOPS Level IIISO 3449:2005 (Optional)

Dimensions

-

Wheel Base54.6 in 1386 mm

-

Height - Top of Cab86.2 in 2189 mm

-

Vehicle Width over Tires72 in 1830 mm

-

Ground Clearance8 in 202 mm

-

Departure Angle23.6°

-

Maximum Dump Angle43.5°

-

Maximum Overall Height164.3 in 4174 mm

-

Bucket Pin Reach - Maximum Lift12.6 in 320 mm

-

Turning Radius from Center - Machine Rear74.7 in 1897 mm

-

Turning Radius from Center - Coupler57.9 in 1471 mm

-

Reach - Maximum Lift/Dump30.9 in 786 mm

-

Turning Radius from Center - Bucket87.7 in 2228 mm

-

Bucket Pin Height - Maximum Lift133.5 in 3391 mm

-

Roll Back Angle28°

-

Maximum Reach - With Arms Parallel to Ground48 in 1220 mm

-

Clearance at Maximum Lift and Dump105.4 in 2676 mm

-

Length - Without Bucket128.7 in 3270 mm

-

Bucket Pin Height - Carry Position8.7 in 220 mm

-

Length - With Bucket on Ground153.9 in 3908 mm

-

NoteOperating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, one speed, 1883 mm (74 in) low profile bucket, Cat 12 × 16.5 tires, standard flow hydraulics, enclosed cab with glass door, mechanical suspension seat, advanced display, 1000 CCA battery, front counterweight, no optional counterweights and manual quick coupler (unless otherwise noted).

-

Rack Back Angle - Maximum Height88°

Engine

-

Gross Power - SAE J1995:2014100 hp 75 kW

-

Net Power - SAE 1349100 hp 74 kW

-

Displacement221 in³ 3.6 l

-

Stroke4.7 in 120 mm

-

Bore3.9 in 98 mm

-

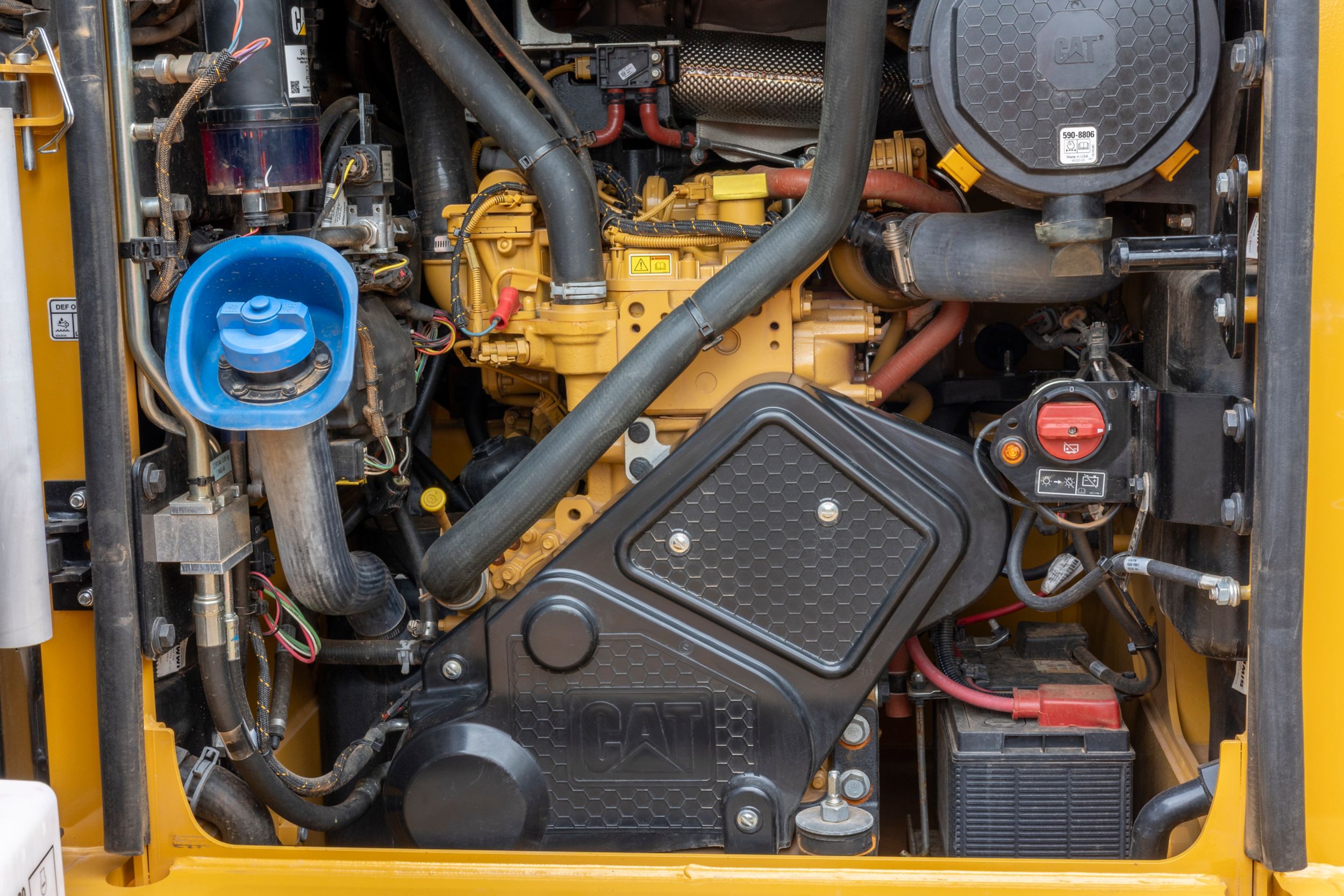

Engine ModelCat C3.6TA (turbocharged, aftercooled)

-

NoteAdvertised power is tested per the specified standard in effect at the time of manufacture. Net power advertised is the power available at the flywheel when the engine is equipped with fan at minimum speed, air intake system, exhaust system, and alternator.

-

Net Power - ISO 924999 hp 74 kW

-

Peak Torque - 1,600 rpm - SAE J1995333 lb/ft 451 N·m

Hydraulic System

-

Hydraulic Flow - High Flow XPS - Maximum Loader Hydraulic Flow34 gpm 129 L/min

-

Hydraulic Flow - Standard - Hydraulic Power (Calculated)46.4 hp 34.6 kW

-

Hydraulic Flow - High Flow - Maximum Loader Hydraulic Pressure3500 psi 24130 kPa

-

Hydraulic Flow - Standard - Loader Hydraulic Flow23 gpm 86 L/min

-

Hydraulic Flow - High Flow XPS - Hydraulic Power (Calculated)80.7 hp 60.2 kW

-

Hydraulic Flow - High Flow - Hydraulic Power (Calculated)69.6 hp 51.9 kW

-

Hydraulic Flow - High Flow - Maximum Loader Hydraulic Flow34 gpm 129 L/min

-

Hydraulic Flow - Standard - Loader Hydraulic Pressure3500 psi 24130 kPa

-

Hydraulic Flow - High Flow XPS - Maximum Loader Hydraulic Pressure4061 psi 28000 kPa

Noise Level

-

Note (2)*The declared dynamic operator sound pressure levels per ISO 6396:2008. The measurements were conducted with the cab doors and windows closed and at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds.

-

Outside Cab**101 dB(A)

-

Note (1)Cab and Rollover Protective Structures (ROPS) are standard in North America and Europe.

-

Inside Cab*83 dB(A)

-

Note (3)**The labeled sound power level for the CE marked configurations when measured according to the test procedure and conditions specified in 2000/14/EC.

Operating Specifications

-

Rated Operating Capacity3557 lb 1614 kg

-

Tipping Load7114 lb 3227 kg

-

Breakout Force - Tilt Cylinder8267 lb 3750 kg

-

Breakout Force - Lift Cylinder6349 lb 2880 kg

-

Rated Operating Capacity with Optional Counterweight3914 lb 1786 kg

-

NoteOperating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, one speed, 1883 mm (74 in) low profile bucket, Cat 12 × 16.5 tires, standard flow hydraulics, enclosed cab with glass door, mechanical suspension seat, advanced display, 1000 CCA battery, front counterweight, no optional counterweights and manual quick coupler (unless otherwise noted).

Power Train

-

Travel Speed - Forward or Reverse - Two Speed Option9.6 mile/h 15.4 km/h

-

Travel Speed - Forward or Reverse - One Speed6.6 mile/h 10.6 km/h

Service Refill Capacities

-

Cooling System4.6 gal (US) 17.5 l

-

Engine Crankcase2.4 gal (US) 9 l

-

Fuel Tank34.5 gal (US) 130.7 l

-

Hydraulic System10.8 gal (US) 41 l

-

Hydraulic Tank6.9 gal (US) 26 l

-

Diesel Exhaust Fluid (DEF) Tank2.9 gal (US) 11 l

Sustainability

-

Recyclability93%

Weights

-

Operating Weight10441 lb 4736 kg

-

NoteOperating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, one speed, 1883 mm (74 in) low profile bucket, Cat 12 × 16.5 tires, standard flow hydraulics, enclosed cab with glass door, mechanical suspension seat, advanced display, 1000 CCA battery, front counterweight, no optional counterweights and manual quick coupler (unless otherwise noted).

Benefits

High Performance Power Train

High performance power train provides maximum performance and production capability through the Electronic Torque Management system, optional two speed travel and an electronic hand/foot throttle with decel pedal capability.

Redesigned Operator Station

Redesigned operator station delivers a larger operating environment. Combined with additional seat travel, the 270 provides more space for operators of any size. The optional one-piece, sealed, and pressurized cab offers a clean and quiet workspace with excellent air distribution through optimally placed vents throughout the cab.

Ventilated and Heated High-Back Air Ride Seat

Available ventilated and heated high-back air ride seat and seat-mounted adjustable joystick controls deliver superior operator comfort.

High Flow XPS Auxiliary Hydraulic System

High Flow XPS auxiliary hydraulic system, delivering high flow and high pressure, is available for applications that demand maximum hydraulic work tool performance.

High Horsepower, High Torque Engine

Electronically controlled Cat C3.6TA (turbocharged, aftercooled) engine delivers maximum horsepower across a wide RPM range and provides high torque for increased working performance, no matter the application. The engine meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

Ride Control

Speed sensitive ride control option improves operation on rough terrain, enabling better load retention, increased productivity, and greater operator comfort.

Advanced Touchscreen Monitor

The 20.3 cm (8-inch) Advanced Touchscreen Monitor offers cutting-edge functionality and control that includes an integrated radio, Bluetooth® connectivity, and multi-camera (side-view) option, and supports 32 different language choices.

Advanced Joysticks

The Advanced Joysticks provide unmatched control of machine functions and adjustments within the display without having to remove your hands from the controls. This includes on-joystick navigation of the Advanced Touchscreen Monitor, radio volume up/down/mute, creep activation, creep on/off, creep speed increment/decrement, one-button Smart Attachment control activation, and additional auxiliary control buttons that deliver single-button control of complex attachment functions.

Ground-Level Access

Ground-level access to all daily service and routine maintenance points helps reduce machine downtime for greater productivity.

Cat Attachments

The broad range of performance matched Cat Attachments makes the Cat Skid Steer Loader the most versatile machine on the job site.

Equipment Info

ELECTRICAL

Battery disconnect with lockout feature

RADIO

Radio, none – for open canopy machines and countries not certified for Bluetooth® technology

PRODUCT LINK™

Product Link Basic series PL243

COOLING FAN

On-demand, variable speed hydraulic cooling fan

GUARDING AND SEALING PACKAGES

HD0 – base guarding and sealing (engine air inlet rain cap, front cab-toframe sealing, and hydraulic fill access door)

OPERATOR ENVIRONMENT

Full color LCD monitor: Creep speed control, Drive response adjustment, Implement response adjustment, Drive Power Priority adjustment, Language selection (×32), Multi-operator Anti-theft Security System and Monitoring, Maintenance schedule and reminders, Event and Diagnostic Code monitoring, Date /Time/Units/Brightness settings, and Smart Technology for use with Smart Attachments.

HYDRAULICS

Selectable control pattern – ISO or H

POWER TRAIN

Cat C2.8T turbocharged diesel engine, Meeting U.S. EPA Tier 4 Final and EU Stage V emission standards

OTHER

Auxiliary Hydraulics, Continuous Flow

MANDATORY EQUIPMENT

Auxiliary Hydraulics: Standard or High Flow XPS

PERFORMANCE PACKAGES

Performance Package HP1: Standard Flow Hydraulics

COMFORT PACKAGES

Open canopy: Cup Holder, Cell Phone Pocket, choice of vinyl seat (Mechanical Suspension, High Back/Heated/Air Ride Seat

TECHNOLOGY PACKAGES

T2 – Standard Joysticks, Standard Monitor, Key Start, Rear-view camera.

Product Brochures