735 Bare Chassis

Specifications

Engine

-

Engine ModelCat® C13

-

Bore5.1 in 130 mm

-

Stroke6.2 in 157 mm

-

Displacement736 in³ 12.5 l

-

Gross Power - SAE J1995:2014434 hp 324 kW

-

Net Power - SAE J1349:2011424 hp 316 kW

-

Peak Engine Torque Gross (SAE J1995)1614 lb/ft 2188 N·m

-

Peak Engine Torque Speed1200 r/min 1200 r/min

-

Peak Engine Torque Net (SAE J1349)1597 lb/ft 2165 N·m

-

Net Power - ISO 14396447 hp 333 kW

-

No Engine De-rating Required Below12500 ft 3810 m

-

Engine Model - U.S. EPA Tier 4 Final/EU Stage IV/Japan 2014 (Tier 4 Final)/Korea Tier 4 FinalCat® C13

Service Refill Capacities

-

Fuel Tank108.8 gal (US) 412 l

-

Cooling System21.9 gal (US) 83 l

-

Hydraulic System29.1 gal (US) 110 l

-

Engine Crankcase10 gal (US) 38 l

-

Transmission12.3 gal (US) 56 l

-

Final Drives/Differential33 gal (US) 125 l

-

Output Transfer Gear Box5.5 gal (US) 25 l

-

DEF Tank5.3 gal (US) 20 l

Sound Levels

-

Interior Cab72 dB(A) 72 dB(A)

Standards

-

BrakesISO 3450:2011

-

Cab - FOPSISO 3449:2005 Level II

-

Cab - ROPSISO 3471:2008

-

SteeringISO 5010:2019

Steering

-

Lock to Lock4.75 seconds at 60 rpm

Transmission

-

Forward - 15 mile/h 8 km/h

-

Forward - 29 mile/h 15 km/h

-

Forward - 314 mile/h 23 km/h

-

Forward - 422 mile/h 35 km/h

-

Forward - 530 mile/h 48 km/h

-

Forward - 635 mile/h 57 km/h

-

Reverse - 16 mile/h 9 km/h

Turning Circle

-

Turning Dimensions - SAE Turning Radius294 in 7470 mm

-

Turning Dimensions - Inside Radius149 in 3793 mm

-

Turning Dimensions - Aisle Width212 in 5393 mm

-

Turning Dimensions - Clearance Radius318 in 8075 mm

-

Turning Dimensions - Steer Angle - Left/Right45°

-

NoteDimensions are for machines equipped with 750/65 R25 tires.

Weights

-

Rated Payload43.1 ton (US) 39.1 t

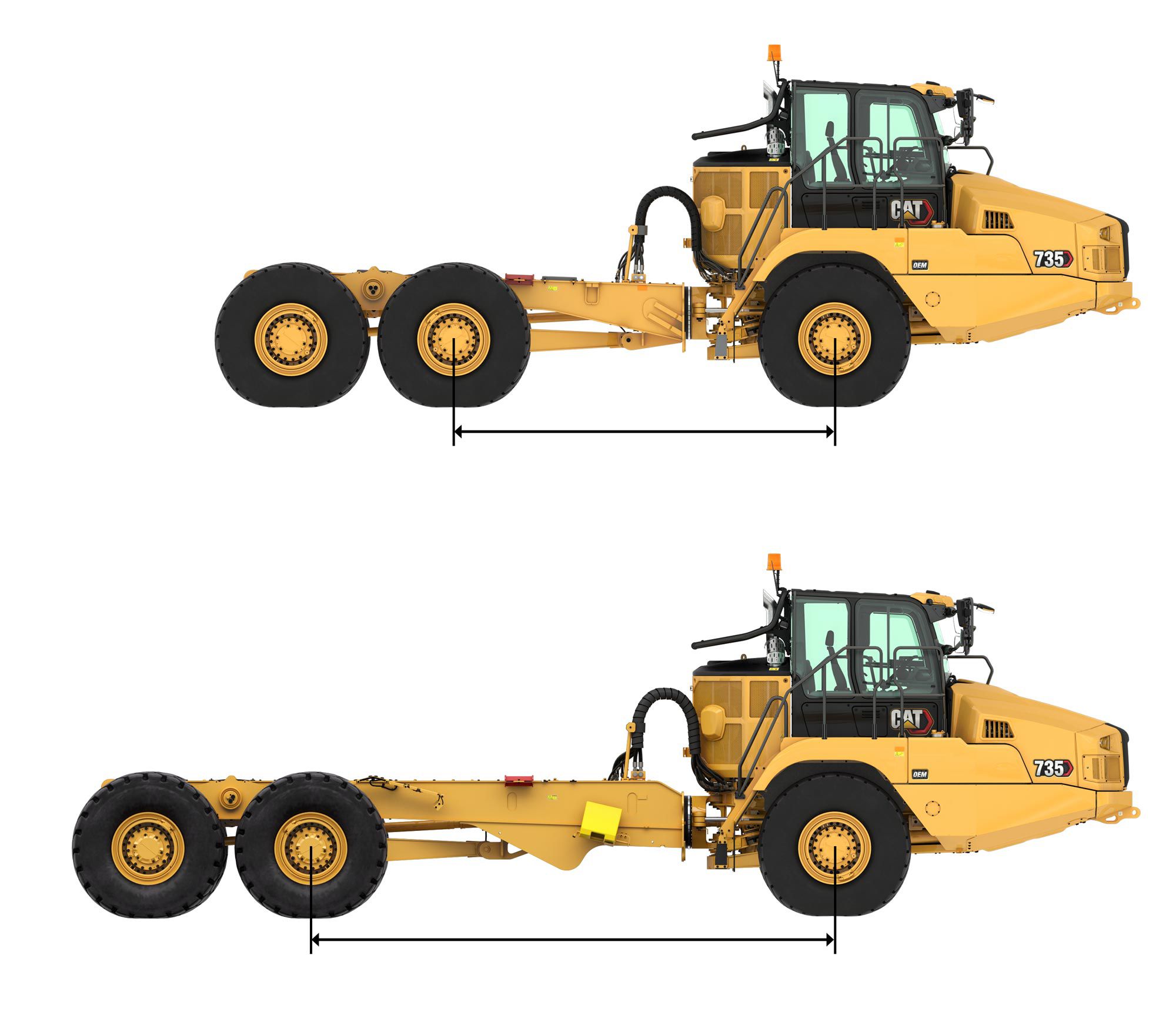

Wheel Base Length

-

Standard Wheel Base156.7 in 3979 mm

-

Long Wheel Base215.2 in 5465 mm

Benefits

Long Wheel Base

- The 735 can be ordered with or without hoist cylinders, and in standard wheel base (SWB) or long wheel base (LWB) configurations through your local Cat dealer.

Water Truck Applications

- Cat® Articulated Truck Bare Chassis are rugged and reliable platforms for water truck applications in both mining and construction projects.

- Using an articulated truck bare chassis provides a flexible solution that is ideal for dust suppression, road construction, fire protection, and other applications.

- Caterpillar works with OEMs worldwide to match various size water tanks with our bare chassis machines, all through your local Cat dealer, to provide the best solution for your business.

Service Truck Applications

- Cat Articulated Truck Bare Chassis are rugged and reliable platforms for service truck applications in both mining and construction projects.

- Using an articulated truck bare chassis provides a flexible solution that is ideal for delivering fuel and preventive maintenance lubrication to your site's machine fleet.

- Caterpillar works with OEMs worldwide to match various size service tanks with our bare chassis machines, all through your local Cat dealer, to provide the best solution for your business.

Specialty Body Applications

- Cat Articulated Truck Bare Chassis are rugged and reliable platforms for specialty body applications.

- Using an articulated truck bare chassis provides a flexible solution that is ideal for hauling coal or waste, container trucks or hooklifts, cable reel trucks, and other applications.

- Caterpillar works with OEMs worldwide to match various size service tanks with our bare chassis machines, all through your local Cat dealer, to provide the best solution for your business.

Forestry Applications

- Cat Articulated Truck Bare Chassis are rugged and reliable platforms for forestry applications.

- Using an articulated truck bare chassis provides a flexible solution that is ideal for hauling logs and other applications.

- Caterpillar works with OEMs worldwide to match various size service tanks with our bare chassis machines, all through your local Cat dealer, to provide the best solution for your business.

Equipment Info

For more information on 735 Bare Chassis options, please contact Caterpillar OEM Solutions at <a href="mailto:oem_solutions@cat.com">oem_solutions@cat.com</a>.

NOTE

Standard and optional equipment may vary. Consult your Cat dealer for details.

OPERATOR ENVIRONMENT

Secondary steering – electro hydraulic

CAT TECHNOLOGIES

Product Link

ELECTRICAL AND LIGHTING

Horn

POWERTRAIN

Retarder: engine compression brake

SAFETY

Reverse alarm

GUARDS

Axle

OTHER STANDARD EQUIPMENT

Vandalism protection: lockable caps

Product Brochures