938

938

Cat® Small Wheel Loaders provide superior performance and versatility to help you get more done. Built to the same tough standards as the larger Cat Wheel Loaders, these machines are ideal for a wide range of jobs.

Book a Demo

Explore my deals

Specifications

Air Conditioning System

-

Air ConditioningThe air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.9 kg (4.2 lb) of refrigerant which has a CO2 equivalent of 2.717 metric tonnes (2.99 tons).

Axles

-

FrontFixed; Locking differential (standard)

-

RearOscillating ± 11 degrees; Open differential (standard); Limited slip differential (optional)

Buckets

-

Bucket Capacities1.9-5.0 m3 (2.5-6.5 yd3)

Cab

-

ROPSISO 3471:2008

-

FOPSISO 3449:2005 LEVEL II

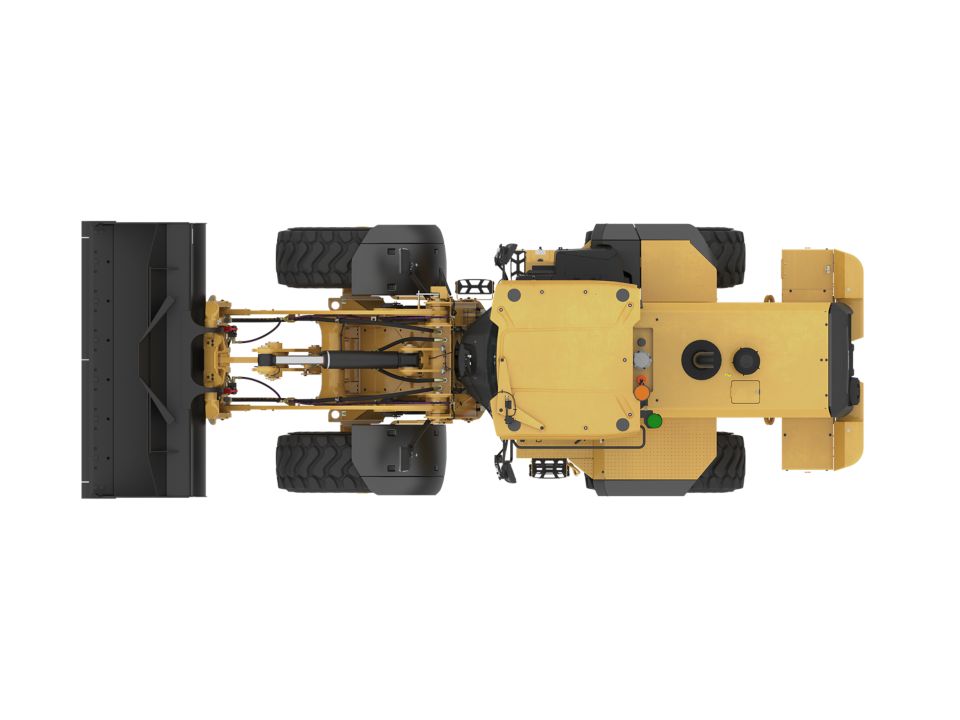

Dimensions with Bucket - High Lift

-

Height - Ground to Cab**10.92 ft 3340 mm

-

Height - Ground to Beacon**12.17 ft 3707 mm

-

Height - Ground to Axle Center**2.25 ft 685 mm

-

Height - Ground Clearance**1.25 ft 386 mm

-

Length - Overall*27.58 ft 8397 mm

-

Length - Rear Axle to Bumper6.42 ft 1968 mm

-

Length - Hitch to Front Axle5 ft 1525 mm

-

Length - Wheel Base10 ft 3050 mm

-

Clearance - Bucket at 45°*11.16 ft 3415 mm

-

Clearance - Load over Height**11.66 ft 3561 mm

-

Clearance - Level Bucket**13.83 ft 4222 mm

-

Height - Bucket Pin**14.92 ft 4550 mm

-

Height - Overall**19.2 ft 5853 mm

-

Reach - Bucket at 45°*4.66 ft 1413 mm

-

Carry Height - Bucket Pin2 ft 612 mm

-

Dig Depth**5.25 in 135 mm

-

Width - Bucket9 ft 2750 mm

-

Width - Tread Center6.83 ft 2083 mm

-

Turning Radius - Over Bucket21.25 ft 6483 mm

-

Width - Over Tires8.83 ft 2693 mm

-

Turning Radius - Outside of Tires18.16 ft 5546 mm

-

Turning Radius - Inside of Tires9.33 ft 2843 mm

-

Rack Angle at Full Lift53 ° 53 °

-

Dump Angle at Full Lift47 ° 47 °

-

Rack Angle at Carry48 ° 48 °

-

Departure Angle33 ° 33 °

-

Articulation Angle40 ° 40 °

-

Operating Weight36210 lb 16425 kg

-

Note (1)*Vary with bucket.

-

Note (2)**Vary with tire.

-

Note (3)Dimensions listed are for a machine configured with 2.5 m³ (3.2 yd³) general purpose Fusion™ bucket, bolt-on cutting edge, standard counterweights, additional guarding, 80 kg (176 Ib) operator and 20.5 R25 (L-3) XHA2 tires.

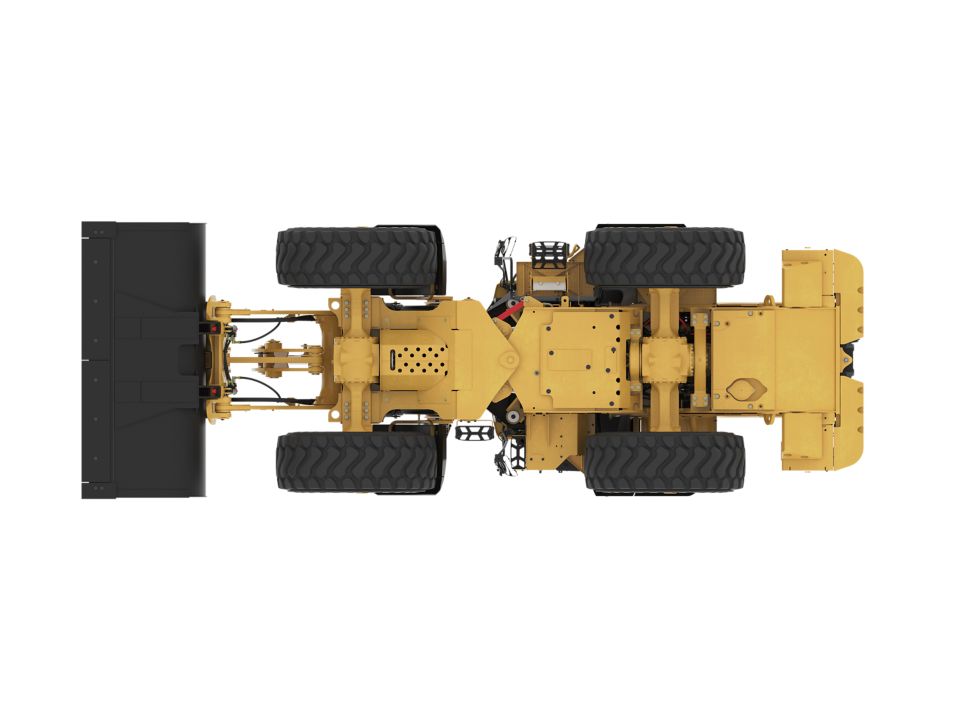

Dimensions with Bucket - Standard Lift

-

Height - Ground to Cab**10.92 ft 3340 mm

-

Height - Ground to Beacon**12.17 ft 3707 mm

-

Height - Ground to Axle Center**2.25 ft 685 mm

-

Height - Ground Clearance**1.25 ft 386 mm

-

Length - Overall*25.08 ft 7656 mm

-

Length - Rear Axle to Bumper6.42 ft 1968 mm

-

Length - Hitch to Front Axle5 ft 1525 mm

-

Length - Wheel Base10 ft 3050 mm

-

Clearance - Bucket at 45°*9.3 ft 2834 mm

-

Clearance - Load over Height**11 ft 3354 mm

-

Clearance - Level Bucket**11.9 ft 3641 mm

-

Height - Bucket Pin**13 ft 3969 mm

-

Height - Overall**17.33 ft 5273 mm

-

Reach - Bucket at 45°*3.75 ft 1146 mm

-

Carry Height - Bucket Pin1.33 ft 394 mm

-

Dig Depth**4 in 101 mm

-

Width - Bucket9 ft 2750 mm

-

Width - Tread Center6.83 ft 2083 mm

-

Turning Radius - Over Bucket20.08 ft 6120 mm

-

Width - Over Tires8.83 ft 2693 mm

-

Turning Radius - Outside of Tires18.16 ft 5546 mm

-

Turning Radius - Inside of Tires9.33 ft 2843 mm

-

Rack Angle at Full Lift54 ° 54 °

-

Dump Angle at Full Lift49 ° 49 °

-

Rack Angle at Carry43 ° 43 °

-

Departure Angle33 ° 33 °

-

Articulation Angle40 ° 40 °

-

Operating Weight35528 lb 16115 kg

-

Note (1)*Vary with bucket.

-

Note (2)**Vary with tire.

-

Note (3)Dimensions listed are for a machine configured with 2.5 m³ (3.2 yd³) general purpose Fusion™ bucket, bolt-on cutting edge, standard counterweights, additional guarding, 80 kg (176 Ib) operator and 20.5 R25 (L-3) XHA2 tires.

Engine

-

Rated Gross Power - SAE J1995191 hp 143 kW

-

Engine ModelCat C7.1*

-

Performance ModeAutomatic

-

Rated Gross Power - Rated Engine Speed1800 r/min 1800 r/min

-

Rated Gross Power - SAE J1995 (DIN)194 mhp 194 mhp

-

Rated Engine Power - ISO 14396188 hp 140 kW

-

Rated Engine Power - ISO 14396 (DIN)191 mhp 191 mhp

-

Rated Net Power - SAE J1349 at Minimum Fan Speed185 hp 138 kW

-

Rated Net Power - ISO 9249 at Minimum Fan Speed185 hp 138 kW

-

Rated Net Power - ISO 9249 (DIN) at Minimum Fan Speed188 mhp 188 mhp

-

Maximum Gross Torque - Engine Speed1400 r/min 1400 r/min

-

Maximum Gross Torque - SAE J1995673 ft·lbf 912 N·m

-

Maximum Gross Torque - ISO 14396664 ft·lbf 900 N·m

-

Maximum Net Torque - SAE J1349656 ft·lbf 889 N·m

-

Maximum Net Torque - ISO 9249658 ft·lbf 892 N·m

-

Displacement427 in³ 7.01 l

-

Bore4 in 105 mm

-

Stroke5 in 135 mm

-

Note*Meets U.S EPA Tier 4 Final, EU Stage V off-highway, and Japan 2014 emission standards.

-

Note (1)Advertised power is tested per the specified standard in effect at the time of manufacture

-

Note (2)Net power ratings are tested at the reference conditions for the specified standard and denote power available at the flywheel when engine is equipped with alternator, air cleaner, emission components and fan at specified speed.

-

Note (3)No derating required up to 3000 m (10,000 ft) altitude. Auto derate protects hydraulic and transmission systems.

Loader Hydraulic System

-

Maximum Flow - Implement Pump50 gpm 190 L/min

-

Maximum Flow - Implement Pump - 3rd Function Maximum Flow*50 gpm 190 L/min

-

Maximum Flow - Implement Pump - 4th Function Maximum Flow*42 gpm 160 L/min

-

Maximum Working Pressure - Implement Pump4061 psi 28000 kPa

-

Relief Pressure - Tilt Cylinder4351 psi 30000 kPa

-

Relief Pressure - Tilt Cylinder - 3rd and 4th Function Maximum Working Pressure4061 psi 28000 kPa

-

Relief Pressure - Tilt Cylinder - 3rd and 4th Function Relief Pressure4351 psi 30000 kPa

-

Lift Cylinder: Standard Lift Linkage - Bore Diameter4.7 in 120 mm

-

Lift Cylinder: Standard Lift Linkage - Rod Diameter2.6 in 65 mm

-

Lift Cylinder: Standard Lift Linkage - Stroke31.1 in 789 mm

-

Tilt Cylinder: Standard Lift Linkage - Bore Diameter5.9 in 150 mm

-

Tilt Cylinder: Standard Lift Linkage - Rod Diameter3.5 in 90 mm

-

Tilt Cylinder: Standard Lift Linkage - Stroke21.9 in 555 mm

-

Hydraulic Cycle Time - Raise, Ground Level to Maximum Lift5.5 s 5.5 s

-

Hydraulic Cycle Time - Dump (at Maximum Lift Height)1.5 s 1.5 s

-

Hydraulic Cycle Time - Float Down, Maximum Lift to Ground Level2.7 s 2.7 s

-

Hydraulic Cycle Time - Total Cycle Time9.7 s 9.7 s

-

Note*3rd and 4th function flow is fully adjustable from 20% to 100% of maximum flow through the secondary display when equipped.

Service Refill Capacities

-

Fuel Tank51.5 gal (US) 195 l

-

Cooling System7.9 gal (US) 30 l

-

Engine Crankcase5.3 gal (US) 20 l

-

Transmission - Gear Box2.2 gal (US) 8.5 l

-

Front Axles9.2 gal (US) 35 l

-

Rear Axles9.2 gal (US) 35 l

-

Hydraulic System - Including Tank4.93 gal (US) 170 l

-

Hydraulic Tank23.8 gal (US) 90 l

-

Diesel Exhaust Fluid (DEF) Tank5 gal (US) 19 l

-

NoteDEF used in Cat systems must meet the requirements outlined in the International Organization for Standardization (ISO) standard 22241-1:2019.

Sound

-

Operator Sound Pressure (ISO 6396:2008)68 dB(A) 68 dB(A)

-

Average Exterior Sound Pressure (ISO 6395:2008)101 dB(A) 101 dB(A)

-

Note (1)European Union Directive 2000/14/EC and UK Noise Regulation 2001 No. 1701.

Steering

-

Steering Cylinder - Bore Diameter3.1 in 80 mm

-

Steering Cylinder - Rod Diameter2 in 50 mm

-

Steering Cylinder - Stroke15.7 in 399 mm

-

Maximum Flow - Steering Pump34 gpm 130 L/min

-

Maximum Working Pressure - Steering Pump3500 psi 24130 kPa

-

Steering Cycle Times (Full Left to Full Right) - Minimum RPM: Pump Flow Limited3.1 s 3.1 s

-

Steering Cycle Times (Full Left to Full Right) - Maximum RPM: 90 RPM Steering Wheel Speed2.3 s 2.3 s

Sustainability

-

Recyclability96%

Tires

-

Standard Size20.5 R25, radial (L-3)

-

Other Choices Include20.5 R25, radial (L-2), 20.5 R25, radial (L-5), 20.5-25 12PR (L-2), 20.5-25 12PR (L-3), 20.5-25 16PR (L-5), 17.5 R25, radial (L-2), 17.5 R25, radial (L-3), 17.5 R25, radial (L-5), 550/65 R25 radial (L-3), Skidder/Agriculture

-

Note (1)Other tire choices are available. Contact your Cat dealer for details.

-

Note (2)In certain applications, the loader’s productive capabilities may exceed the tire’s tonnes-km/h (ton-mph) capabilities.

-

Note (3)Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model.

Transmission

-

Forward and Reverse - Range 1*1-13 km/h (0.6-8 mph)

-

Forward and Reverse - Range 28 mile/h 13 km/h

-

Forward and Reverse - Range 317 mile/h 27 km/h

-

Forward and Reverse - Range 425 mile/h 40 km/h

-

Note*Creeper control allows maximum speed range adjustability from 1 km/h (0.6 mph) to 13 km/h (8 mph) in Range 1 through the secondary display when equipped. Factory default is 7 km/h (4.4 mph).

Weights

-

Operating Weight35528 lb 16115 kg

-

Operating Weight - High Lift36210 lb 16425 kg

Benefits

Enjoy All Day Comfort

- Have a seat in the new Cat small wheel loader and enjoy automatic temperature control, class leading sound levels, enhanced all-around visibility and low-effort joystick controls that move with you on a fully adjustable seat suspension. A large spacious operator environment combined with Caterpillar hydraulic cylinder damping and smooth predictable controls make this the most comfortable seat on your jobsite.

- An upgrade to multi-view camera and rear object detection gives you an extra eye on the jobsite while the new optional force feedback joystick steering keeps you feeling confident on those long shifts. The operator not present function helps to isolate the machine if you leave the environment; while seat belt notifications give you a gentle reminder to buckle up.

Efficiently Powerful

- Experience the difference with an intelligent hydrostatic power train and industry leading fuel savings through a lower maximum engine speed working in combination with a new auto engine RPM mode. This provides efficiency as standard with a boost in power when you need it. Optimize traction and minimize wheel slip with a new Auto Wheel Torque system tuned to provide peak performance while maximizing tire life and keeping operating costs low. Track your production and accurately hit your load targets with Cat Payload. 250 hours of Cat Payload demonstration will be included as standard with an optional subscription for extended use.

Work Made Easy

- Move more with the Caterpillar patented quick loading performance series buckets and optimized Z-bar linkage with enhanced forward visibility that combines the digging efficiency of a traditional Z-bar with tool carrier capabilities. The parallel lift and high tilt forces throughout the working range allow you to confidently handle loads with precise control.

- Multi-function work has never been easier with dedicated pumps for each system and a flow sharing implement valve governed by an intelligent power management system. Simultaneously lift, steer, and drive without compromise. Upgrade to autolube and tire pressure monitoring to make service easy and get to work quicker. Light the way with auto roading lights that come on at night fall.

Customize Your Experience

- Meet your application requirements and individual preferences with Caterpillar industry first Hystat™ Operator Modes featuring four unique power train settings. Select classic torque converter for smooth rollout, conventional hystat for aggressive engine braking, an ice mode that maximizes your control on slippery underfoot, and an all new single pedal mode for simplified use.

- Fine tune machine performance with adjustments at your fingertips through programmable joysticks, soft touch buttons, and a new jog dial that works in combination with a standard touch screen display. Quickly recall attachment profiles that maintain key settings for versatility on the jobsite and optimal efficiency.

Upgrades and Services

- Enjoy a full range of upgrades and accessories to configure your small wheel loader for a broader range of applications.

- Utilize readily available services and maintenance parts, including a range of self-service options (SSO) and dealer installed kits.

Purpose Built: Handlers Arrangements - Aggregate Handler

- Increased Payload: Additional counterweight improves stability without reducing ground clearance or departure angle to maximize performance.

- Long Life Sand and Gravel Buckets: Performance series buckets deliver higher fill factors and better material retention for significant productivity and fuel efficiency improvements. Buckets feature a long floor, open throat, curved side bars and additional serviceable wear plates including corner guards.

- Protect your Power Train: Increase your fording depth with optional elevated breathers. Remote mounted high on the machine for the front and rear axles and hydrostatic gear box. Allows settling pond cleanout without contamination.

Purpose Built: Handlers Arrangements - Waste Handler

- Guard Your Investment: Choose from a complete range of optional guarding to protect your machine from the harsh environment of a waste handling application. Machine guarding is purpose built to protect the machine’s major components.

- Breathe Clean: Maximize your engine life and extend filter cleaning intervals with a turbine pre-cleaner. Keep cool with a reversing fan to purge the single plane, widely spaced core cooling package and brush-less sealed alternator. Breathe clean with a powered pre-cleaner for the operator environment.

- Maximize Tire Life: Fine tune your wheel torque to match the underfoot conditions and maximize performance while extending tire life. Standard auto wheel torque and auto differential lock are ideal for waste handling applications.

Sustainability

- The Cat® C7.1 engine meets U.S. EPA Tier 4 Final, EU Stage V and Korea Tier 5 emission standards.

- Engine Idle Management System (EIMS) helps maximize fuel efficiency and reduce greenhouse gas emissions while maintaining machine performance.

- Engine Idle Shutdown Timer reduces fuel burn, greenhouse gas emissions and unnecessary idle time by shutting down the machine after a pre-set idling period.

- Performance Series Buckets have rounded side boards, a longer floor and open angle to carry more and load quicker so each pass is the most efficient.

- Rimpull Control is a quick way to adjust the torque to the tires for less slipping and tire wear.

- Cat® Production Measurement provides real-time payload weighing which help you maximize productivity, reduce fuel burn and greenhouse gas emissions, all while improving job site efficiency and lowering costs.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- Power on Demand, transparent to the operator, provides full-time efficiency and power when you need it.

- Tire Pressure Monitoring provides real-time tire pressure information to the operator to help increase tire wear and achieve better fuel efficiency and reduced greenhouse gas emissions.

- Intelligent Hystat Transmission helps improves control and reduces fuel consumption and greenhouse gas emissions in load and carry applications.

- Variable Displacement Pumps match power to load as application requirements change.

Equipment Info

NOTE: Not all features are available in all regions.

OPERATOR ENVIRONMENT

75 mm (3 in) retractable seatbelt

POWER TRAIN

Cat C7.1 engine

HYDRAULICS

Automatic lift and bucket kickouts, adjustable in-cab

ELECTRICAL

Alternator, 115-amp, heavy duty

OTHER

Large-access enclosure doors with adjustable close/open force

Product Brochures