Conditional Content 1

Conditional Content 2

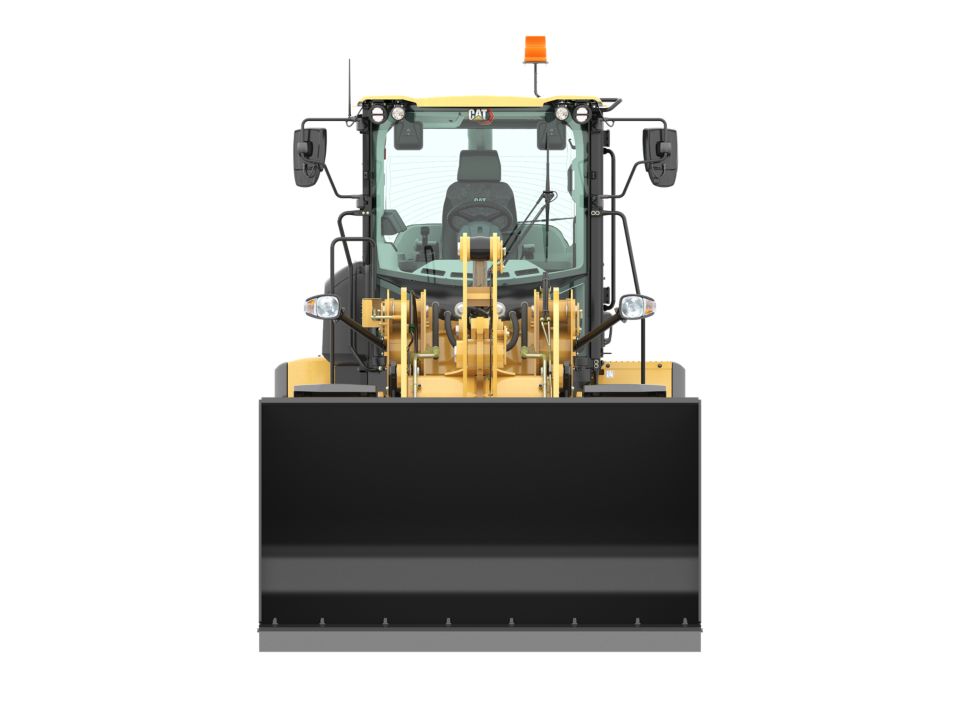

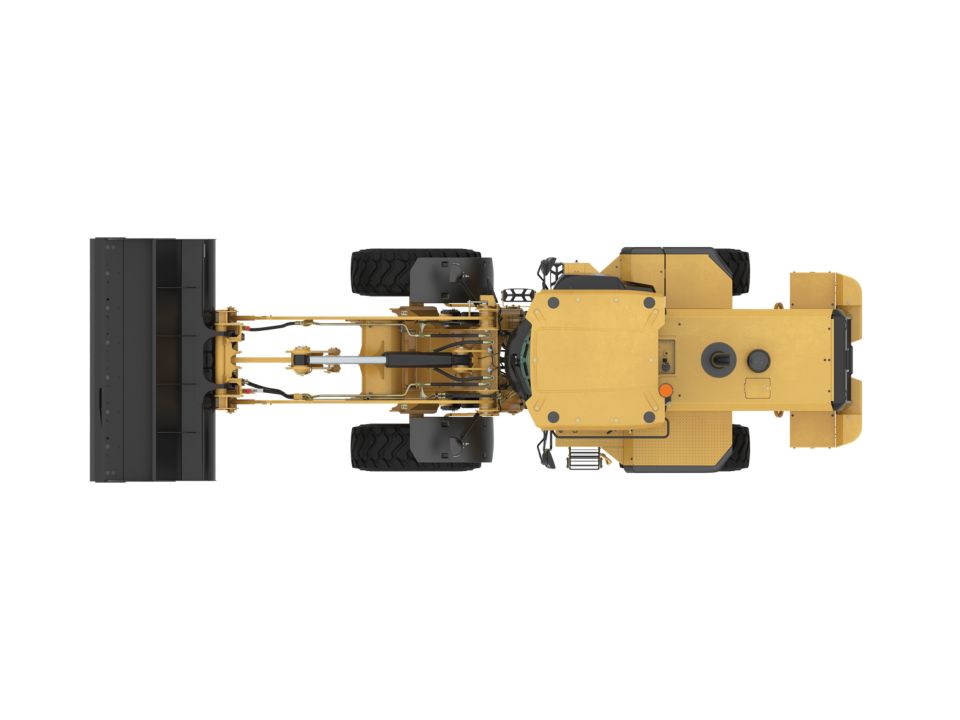

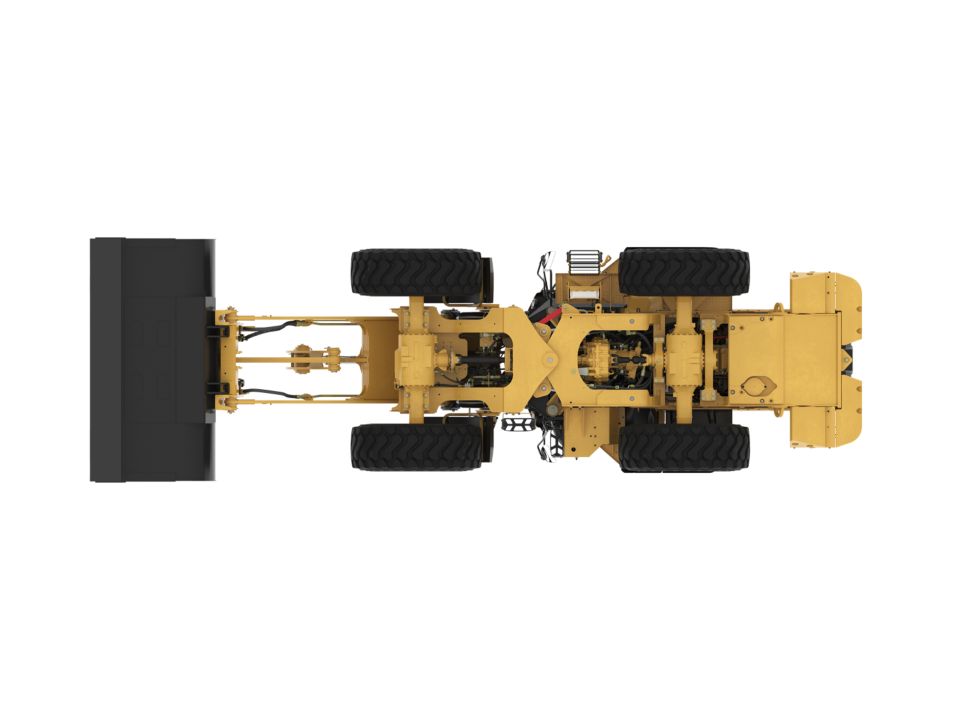

930M Ag Handler

930M Ag Handler

Cat® Small Wheel Loaders provide superior performance and versatility to help you get more done. Built to the same tough standards as the larger Cat Wheel Loaders, these machines are ideal for a wide range of jobs.

Book a Demo

Explore my deals

Specifications

Air Conditioning System

-

Air ConditioningThe air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.9 kg of refrigerant which has a CO2 equivalent of 2.717 metric tonnes.

Axles

-

RearOscillating ±11 degrees; Open differential (standard); Limited slip differential (optional)

-

FrontFixed; Locking differential (standard)

Buckets

-

Bucket Capacities2.1-5.0 m³ (2.7-6.5 yd³)

-

Bucket Capacities - Light Material3.1-5.0 m³ (4.0-6.5 yd³)

Cab

-

ROPSISO 3471:2008

-

FOPSISO 3449:2005 Level II

-

Declared Sound Levels - Exterior Sound Power Level (ISO 6395:2008)*101 dB(A) 101 dB(A)

-

Declared Sound Levels - Operator Sound Pressure Level (ISO 6396:2008)*68 dB(A) 68 dB(A)

-

Note (1)*The measurements were conducted at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds. The cab was properly installed and maintained. The measurements were conducted with the cab doors and the cab windows closed.

Dimensions with Bucket - High Lift

-

Length - Rear Axle to Bumper6.5 ft 1993 mm

-

Departure Angle33 ° 33 °

-

Height - Overall**18.7 ft 5698 mm

-

Reach - Bucket at 45°*4.4 ft 1339 mm

-

Dump Angle at Full Lift48 ° 48 °

-

Width - Bucket8.4 ft 2550 mm

-

Length - Wheel Base9.8 ft 3000 mm

-

Width - Tread Center6.3 ft 1930 mm

-

Length - Hitch to Front Axle4.9 ft 1500 mm

-

Height - Ground to Axle Center**2.25 ft 685 mm

-

Note (1)*Vary with bucket.

-

Clearance - Bucket at 45°*10.7 ft 3272 mm

-

Height - Bucket Pin**14.4 ft 4400 mm

-

Height - Ground to Beacon**12.2 ft 3707 mm

-

Carry Height - Bucket Pin1.9 ft 582 mm

-

Clearance - Load over Height**11.6 ft 3550 mm

-

Turning Radius - Outside of Tires17.7 ft 5402 mm

-

Turning Radius - Over Bucket20.6 ft 6272 mm

-

Rack Angle at Full Lift51 ° 51 °

-

Rack Angle at Carry47 ° 47 °

-

Length - Overall*27 ft 8235 mm

-

Note (2)**Vary with tire.

-

Height - Ground to Cab**10.9 ft 3340 mm

-

Turning Radius - Inside of Tires9.4 ft 2851 mm

-

Clearance - Level Bucket**13.4 ft 4073 mm

-

Width - Over Tires8.3 ft 2540 mm

-

Note (3)Dimensions listed are for a 930M Ag Handler configured with General Purpose 2.3 m³ (3.0 yd³) Fusion bucket, bolt-on cutting edges, heavy counterweights, 80 kg (176 lb) operator, and Michelin 20.5 R25 XHA2 tires.

-

Dig Depth**5.3 in 135 mm

-

Articulation Angle40 ° 40 °

-

Operating Weight31441 lb 14262 kg

-

Height - Ground Clearance**1.3 ft 397 mm

Dimensions with Bucket - Standard Lift

-

Height - Ground Clearance**1.3 ft 397 mm

-

Rack Angle at Carry43 ° 43 °

-

Departure Angle33 ° 33 °

-

Length - Wheel Base9.8 ft 3000 mm

-

Length - Rear Axle to Bumper6.5 ft 1993 mm

-

Turning Radius - Over Bucket19.5 ft 5952 mm

-

Carry Height - Bucket Pin1.3 ft 390 mm

-

Width - Over Tires8.3 ft 2540 mm

-

Note (2)**Vary with tire.

-

Dig Depth**3.9 in 100 mm

-

Turning Radius - Outside of Tires17.7 ft 5402 mm

-

Clearance - Level Bucket**11.75 ft 3580 mm

-

Clearance - Bucket at 45°*9.1 ft 2779 mm

-

Rack Angle at Full Lift54 ° 54 °

-

Height - Overall**17.1 ft 5205 mm

-

Width - Bucket8.4 ft 2550 mm

-

Height - Ground to Axle Center**2.25 ft 685 mm

-

Height - Bucket Pin**12.8 ft 3907 mm

-

Operating Weight31125 lb 14118 kg

-

Width - Tread Center6.3 ft 1930 mm

-

Turning Radius - Inside of Tires9.4 ft 2851 mm

-

Reach - Bucket at 45°*3.6 ft 1102 mm

-

Length - Overall*24.9 ft 7593 mm

-

Clearance - Load over Height**10.9 ft 3331 mm

-

Length - Hitch to Front Axle4.9 ft 1500 mm

-

Height - Ground to Beacon**12.2 ft 3707 mm

-

Articulation Angle40 ° 40 °

-

Height - Ground to Cab**10.9 ft 3340 mm

-

Note (3)Dimensions listed are for a 930M Ag Handler configured with General Purpose 2.3 m³ (3.0 yd³) Fusion bucket, bolt-on cutting edges, heavy counterweights, 80 kg (176 lb) operator, and Michelin 20.5 R25 XHA2 tires.

-

Note (1)*Vary with bucket.

-

Dump Angle at Full Lift48 ° 48 °

Engine

-

Maximum Gross Power168 hp 125 kW

-

Maximum Gross Torque - ISO 14396 (Performance Power Mode: Range 1-4)601 ft·lbf 815 N·m

-

Stroke - Performance Power Mode: Range 1-45.3 in 135 mm

-

Maximum Gross Power - Maximum Engine Speed (Performance Power Mode: Range 1-4)1800 r/min 1800 r/min

-

Maximum Net Torque - SAE J1349 (Performance [HP+] Power Mode: Range 1-4)797 N·m 588 ft·lbf

-

Displacement (Performance Power Mode: Speed Range 1-4)428 in³ 7.01 l

-

EmissionsEngine meets U.S. EPA Tier 4 Final emission standards.

-

Engine ModelCat® C7.1

-

Note (4)No derating required up to 3000 m (10,000 ft) altitude. Auto derate protects hydraulic and transmission systems.

-

Maximum Rated Gross Power - ISO 14396168 hp 125 kW

-

Maximum Gross Power - ISO 14396 (DIN) (Performance Power Mode: Range 1-4)170 hp 127 kW

-

Note (2)**Range 4 power and torque is equal to Performance Mode with Caterpillar Power by Range technology.

-

Note (3)Net power ratings are tested at the reference conditions for the specified standard and denote power available at the flywheel when the engine is equipped with alternator, air cleaner, emission components and fan at specified speed.

-

Maximum Gross Power - ISO 14396 (Performance Power Mode: Range 1-4)168 hp 125 kW

-

Note (1)*The Cat C7.1 engine meets U.S. EPA Tier 4 Final/EU Stage V emission standards.

-

Bore (Standard Power Mode: Range 1-4)4.1 in 105 mm

-

Net Power - ISO 9249 at Minimum Fan Speed (Standard Power Mode: Range 1-3**)156 hp 116 kW

-

Stroke (Standard Power Mode: Range 1-3**)5.3 in 135 mm

-

Net Power - SAE J1349 at Minimum Fan Speed (Standard Power Mode: Range 1-3**)156 hp 116 kW

-

Maximum Gross Power - Maximum Engine Speed (Standard Power Mode: Range 1-3**)1600 r/min 1600 r/min

-

Net Power - ISO 9249 (metric) at Minimum Fan Speed (Performance Power Mode: Range 1-4)166 hp 166 hp

-

Net Power - ISO 9249 at Minimum Fan Speed (Performance Power Mode: Range 1-4)164 hp 122 kW

-

Net Power - ISO 9249 (metric) at Minimum Fan Speed (Standard Power Mode: Range 1-3**)158 hp 158 hp

-

Bore (Standard Power Mode: Range 1-3**)4.1 in 105 mm

-

Maximum Net Torque - ISO 9249 (Performance Power Mode: Range 1-4)587 ft·lbf 796 N·m

-

Maximum Gross Torque - ISO 14396 (Standard Power Mode: Range 1-3**)795 N·m 586 ft·lbf

-

Maximum Net Torque - ISO 9249 (Standard Power Mode: Range 1-3**)776 N·m 572 ft·lbf

-

Net Power - SAE J1349 at Minimum Fan Speed (Performance Power Mode: Range 1-4)163 hp 122 kW

-

Displacement (Standard Power Mode: Range 1-3**)428 in³ 7.01 l

-

Maximum Gross Power - ISO 14396 (Standard Power Mode: Range 1-3**)160 hp 119 kW

-

Maximum Gross Power - ISO 14396 (metric) (Standard Power Mode: Range 1-3**)162 hp 162 hp

-

Maximum Net Torque - SAE J1349 (Standard Power Mode: Range 1-3**)573 ft·lbf 777 N·m

-

Maximum Rated Gross Power - ISO 14396 (metric)170 mhp 170 mhp

Loader Hydraulic System

-

Relief Pressure - Tilt Cylinder4351 psi 30000 kPa

-

Cycle Times - 1,600 rpm - Standard: Total Cycle Time10.1 s 10.1 s

-

Maximum Flow - Implement Pump50 gal/min 190 l/min

-

Maximum Flow - Implement Pump - 4th Function Maximum Flow*42 gal/min 160 l/min

-

Note (2)Flow values listed are for a machine running in Performance Power Mode (1,800 rpm).

-

Cycle Times - 1,800 rpm - Performance (HP+): Dump (at Maximum Lift Height)1.5 s 1.5 s

-

Note*3rd and 4th function flow is fully adjustable from 20% to 100% of maximum flow through the secondary display.

-

Cycle Times - 1,800 rpm - Performance (HP+): Total Cycle Time9.3 s 9.3 s

-

Cycle Times - 1,600 rpm - Standard: Float Down (Maximum Lift to Ground Level)2.7 s 2.7 s

-

Cycle Times - 1,800 rpm - Performance (HP+): Raise (Ground Level to Maximum Lift)5.1 s 5.1 s

-

Cycle Times - 1,800 rpm - Performance (HP+): Float Down (Maximum Lift to Ground Level)2.7 s 2.7 s

-

Relief Pressure - Tilt Cylinder - 3rd and 4th Function Maximum Working Pressure4061 psi 28000 kPa

-

Cycle Times - 1,600 rpm - Standard: Dump (at Maximum Lift Height)1.7 s 1.7 s

-

Maximum Working Pressure - Implement Pump4061 psi 28000 kPa

-

Relief Pressure - Tilt Cylinder - 3rd and 4th Function Relief Pressure4351 psi 30000 kPa

-

Note (1)Implement system uses a dedicated load sensing variable displacement pump with dual double acting lift cylinders and a single double acting tilt cylinder.

-

Cycle Times - 1,600 rpm - Standard: Raise (Ground Level to Maximum Lift)5.7 s 5.7 s

-

Maximum Flow - Implement Pump - 3rd Function Maximum Flow*50 gal/min 190 l/min

-

Lift Cylinder: Standard Lift Linkage - Bore Diameter4.3 in 110 mm

-

Tilt Cylinder: Standard Lift Linkage - Stroke21.9 in 555 mm

-

Tilt Cylinder: Standard Lift Linkage - Rod Diameter2.8 in 70 mm

-

Lift Cylinder: Standard Lift Linkage - Rod Diameter2.4 in 60 mm

-

Tilt Cylinder: Standard Lift Linkage - Bore Diameter5.1 in 130 mm

-

Lift Cylinder: Standard Lift Linkage - Stroke28.7 in 728 mm

Operating Specifications

-

Full Turn Tip Load19424 lb 8811 kg

Power Train

-

Note*Differential front locking axle can be engaged on the go at full torque to 10 km/h (6.2 mph).

-

Rear AxleOscillating

-

Note (2)Power train is governed by the Caterpillar exclusive Intelligent Power Management system to deliver peak performance and efficiency.

-

Front AxleFixed

-

Front Axle - Traction Aid*Locking differential standard

-

Rear Axle - Oscillation Angle by Tire Size - 20.5 R25± 10.5 degrees

-

Brakes - ServiceInboard wet disc

-

Rear Axle - Traction AidLimited slip differential optional

-

Brakes - ParkingSpring applied hydraulically released

-

Rear Axle - Oscillation Angle by Tire Size - 750/65, 620/65± 7 degrees

Service Refill Capacities

-

Transmission - Gear Box2.2 gal (US) 8.5 l

-

Cooling System7.9 gal (US) 30 l

-

Diesel Exhaust Fluid (DEF) Tank5 gal (US) 19 l

-

Fuel Tank51.5 gal (US) 195 l

-

Axles - Rear6.6 gal (US) 25 l

-

Hydraulic System - Including Tank43.6 gal (US) 165 l

-

Engine Crankcase5.3 gal (US) 20 l

-

Axles - Front6.9 gal (US) 26 l

-

Hydraulic Tank23.8 gal (US) 90 l

Steering

-

Note (2)Flow values listed are for a machine running in Performance Power Mode (1,800 rpm).

-

Number of Steering Wheel Turns - Full Left to Full Right or Full Right to Full Left3.5 turns 3.5 turns

-

Maximum Flow - Steering Pump34 gal/min 130 l/min

-

Steering Cylinder, Double Acting - Bore Diameter2.8 in 70 mm

-

Steering Cylinder, Double Acting - Stroke17.2 in 438 mm

-

Note (1)Steering system uses a dedicated load sensing variable displacement pump with dual double acting cylinders.

-

Maximum Working Pressure - Steering Pump3500 psi 24130 kPa

-

Steering Cycle Times - Full Left to Full Right - Minimum RPM: Pump Flow Limited2.8 s 2.8 s

-

Steering Articulation Angle - Each Direction40°

-

Steering Cycle Times - Full Left to Full Right - Maximum RPM: 90 rpm Steering Wheel Speed2.4 s 2.4 s

-

Steering Cylinder, Double Acting - Rod Diameter1.6 in 40 mm

Sustainability

-

Recyclability94%

Tires

-

Standard Size20.5 R25, radial (L-3)

-

Note (2)Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model.

-

Note (1)Other tire choices are available. Contact your Cat dealer for details.

-

Other Choices Include20.5 R25, Radial (L-2); 620/75 R26 MegaX, 750/65 R26 MegaX

Transmission

-

Forward - Range 28 mile/h 13 km/h

-

Forward - Range 1*1-13 km/h (0.6-8 mph)

-

Reverse - Range 425 mile/h 40 km/h

-

Reverse - Range 28 mile/h 13 km/h

-

NoteCreeper control allows maximum speed range adjustability in the forward direction from 1 km/h (0.6 mph) to 13 km/h (8 mph) in Range 1 through the secondary display when equipped. Factory default is 7 km/h (4.4 mph). Maximum reverse speed will be maintained at 13 km/h (8 mph) in Range 1 for a quick reverse.

-

Forward - Range 317 mile/h 27 km/h

-

Forward - Range 425 mile/h 40 km/h

-

Reverse - Range 317 mile/h 27 km/h

-

Reverse - Range 1*8 mile/h 13 km/h

Weights

-

Operating Weight31382 lb 14235 kg

Benefits

Efficiently Powerful

Experience hybrid-like fuel efficiency with an intelligent hydrostatic power train and industry leading fuel savings through a lower maximum engine speed of just 1,600 rpm in Standard Mode. Power when you need it with Caterpillar's exclusive Power-by-Range technology that increases power in Range 4 for improved speed on grade. For your toughest and most demanding farm applications a new Performance Mode will allow you to boost the power and hydraulic speed in all Ranges to get the job done even quicker. Meets U.S. EPA Tier 4 Final emission standards with a Cat® C7.1 engine that is designed to manage itself so you can concentrate on your work.

Work Made Easy

Move more with Caterpillar's patented quick loading Performance Series buckets and High Lift optimized Z-bar linkage that combines the digging efficiency of a traditional Z-bar with tool carrier capabilities. The parallel lift and high tilt forces throughout the working range allow you to safely and confidently handle loads from bales to silage with precise control. Multi-function work has never been easier with dedicated pumps for each system and a flow sharing implement valve governed by an intelligent power management system. Simultaneously lift, steer and drive without compromise. A 20% boost in hydraulic speeds on the Ag Handler helps you finish the day on time.

Enjoy All Day Comfort

Have a seat in the 930M Ag Handler and enjoy automatic temperature control, class leading sound levels, excellent all around visibility and low-effort joystick controls that move with you on a fully adjustable seat suspension. A large spacious operator environment combined with Caterpillar's exclusive hydraulic cylinder damping and smooth predictable controls make this the most comfortable seat on the farm.

Customize Your Experience

Fine tune machine performance with adjustments at your fingertips through the soft touch buttons and optional secondary touch screen display. Quickly set auxiliary flow to optimize grapple or silage defacer speed, enable auto reversing fan to breathe clean in dusty environments, toggle over to fine mode for improved control when bale stacking, program linkage kick-out positions for easy feed wagon loading, adjust wheel torque to match underfoot conditions when cleaning corrals and customize ride control activation speed for a smooth loaded carry run. The 930M Ag Handler is ready for the challenge on your farm!

Sustainability

- The Cat® C7.1 engine meets U.S. EPA Tier 4 Final, EU Stage V and Korea Tier 5 emission standards.

- Engine Idle Management System (EIMS) helps maximize fuel efficiency and reduce greenhouse gas emissions while maintaining machine performance.

- Engine Idle Shutdown Timer reduces fuel burn, greenhouse gas emissions and unnecessary idle time by shutting down the machine after a pre-set idling period.

- Performance Series Buckets have rounded side boards, a longer floor and open angle to carry more and load quicker so each pass is the most efficient.

- Rimpull Control is a quick way to adjust the torque to the tires for less slipping and tire wear.

- Cat® Production Measurement provides real-time payload weighing which help you maximize productivity, reduce fuel burn and greenhouse gas emissions, all while improving job site efficiency and lowering costs.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- Power on Demand, transparent to the operator, provides full-time efficiency and power when you need it.

- Tire Pressure Monitoring provides real-time tire pressure information to the operator to help increase tire wear and achieve better fuel efficiency and reduced greenhouse gas emissions.

- Intelligent Hystat Transmission helps improves control and reduces fuel consumption and greenhouse gas emissions in load and carry applications.

- Variable Displacement Pumps match power to load as application requirements change.

Equipment Info

POWER TRAIN

Auto idle shut down feature

HYDRAULICS

Automatic lift lower and tilt kickouts, adjustable in-cab

ELECTRICAL

Alternator, 115 amp, heavy duty

OPERATOR ENVIRONMENT

Cab, pressurized

OTHER STANDARD EQUIPMENT

Cat optimized Z-bar linkage with parallel lift

Product Brochures