903D

903D

Cat® Compact Wheel Loaders deliver high performance, versatility, and precision in any application.

Book a Demo

Explore my deals

Specifications

Buckets

-

Bucket Capacities0.6-1.0 m3 (0.8-1.3 yd3)

-

Bucket Capacities - General Purpose0.6 m3 (0.8 yd3)

-

Bucket Capacities - Light Material1.0 m3 (1.3 yd3)

Cab

-

ROPSISO 3471:2008

-

FOPSISO 3449:2005 Level I

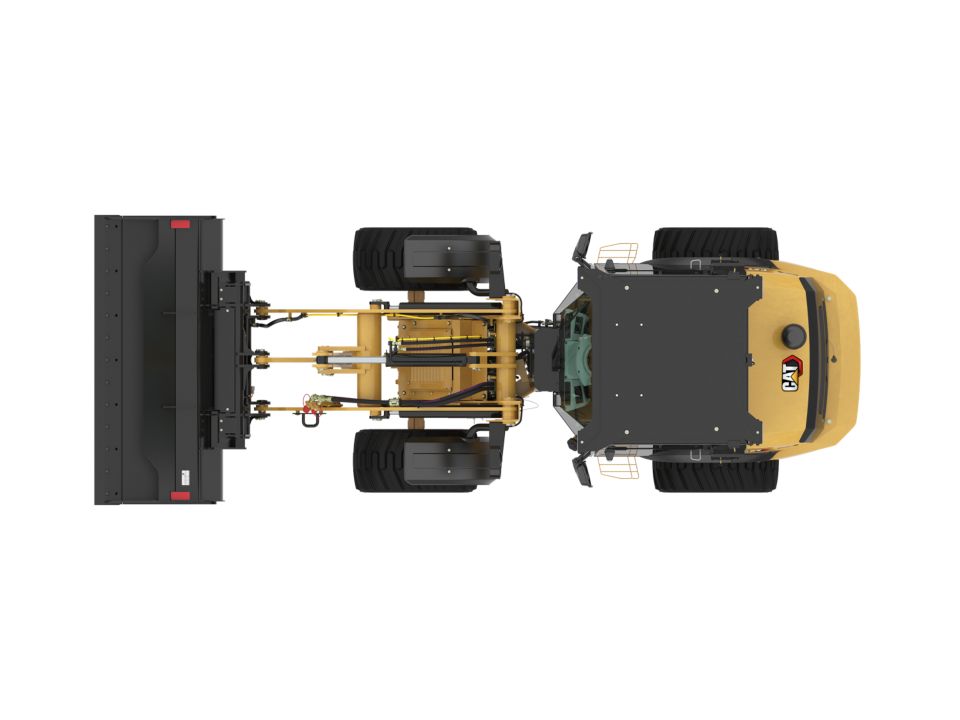

Dimensions (Approximate) - High Lift

-

Cab Height8.25 ft 2510 mm

-

Ground Clearance10 in 250 mm

-

Wheel Base6.42 ft 1950 mm

-

Overall Length - With Bucket*16.17 ft 4936 mm

-

Reach at Maximum Dump Height*2.42 ft 729 mm

-

Dig Depth8 in 195 mm

-

Maximum Dump Height*8 ft 2435 mm

-

Load Over Height9.67 ft 2942 mm

-

Hinge Pin at Maximum Height10.58 ft 3227 mm

-

Departure Angle - Degrees30°

-

Overall Length - With Forks17.58 ft 5363 mm

-

Reach - Ground Level3.25 ft 979 mm

-

Maximum Reach4.92 ft 1486 mm

-

Fork Depth Above Ground2 in 40 mm

-

Fork Height at Maximum Reach4.67 ft 1421 mm

-

Maximum Fork Height10.33 ft 3146 mm

-

Fork Reach at Maximum Height2 ft 609 mm

-

Turning Radius - Over Bucket*13.42 ft 4086 mm

-

Turning Radius - Inside Tire**5.92 ft 1816 mm

-

Width - Over Bucket*5.83 ft 1770 mm

-

Tire Gauge4.33 ft 1314 mm

-

Machine Width**5.58 ft 1708 mm

-

Articulation Angle40°

-

Steering Angle80°

-

Dump Angle at Maximum Height40°

-

Note (1)*Vary with bucket size.

-

Note (2)**Vary with tire size.

-

Note (3)Dimensions listed are based on the machine configured with cab with air conditioning, remote quick coupler, general purpose bucket or 1067 mm (42 in) forks, 75 kg (165 lb) operator, 33 × 15.5-16.5, 12 PR tires, without ride control, without precleaner.

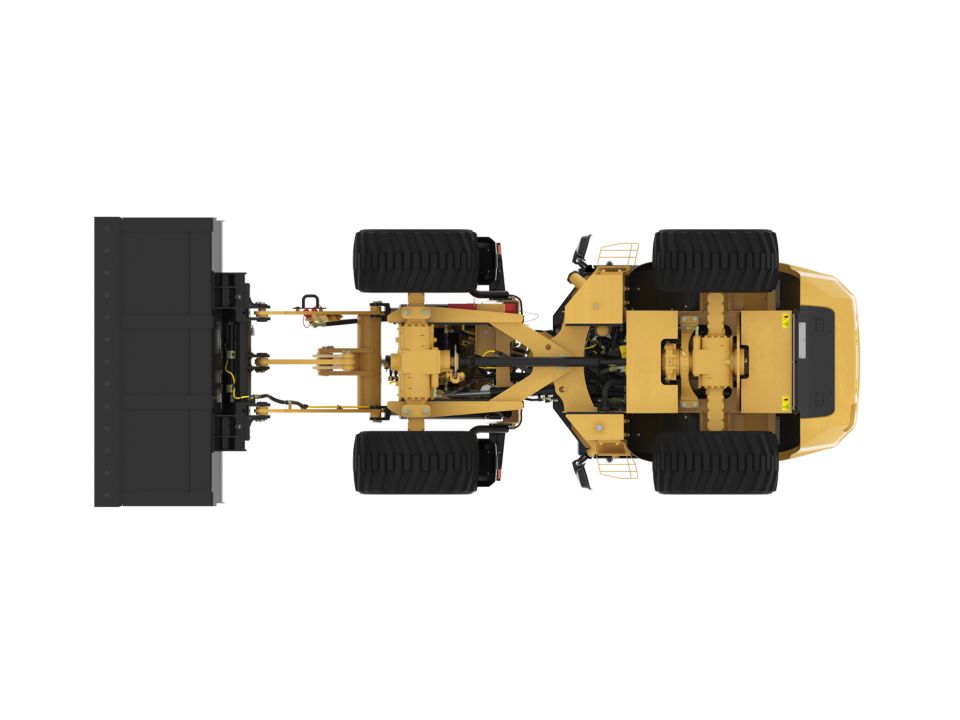

Dimensions (Approximate) - Standard Lift

-

Cab Height8.25 ft 2510 mm

-

Ground Clearance10 in 250 mm

-

Wheel Base6.42 ft 1950 mm

-

Overall Length - With Bucket*15.75 ft 4790 mm

-

Reach at Maximum Dump Height*2.33 ft 720 mm

-

Dig Depth6 in 163 mm

-

Maximum Dump Height*7.5 ft 2292 mm

-

Load Over Height9.17 ft 2801 mm

-

Hinge Pin at Maximum Height10.08 ft 3086 mm

-

Departure Angle - Degrees30°

-

Overall Length - With Forks17.08 ft 5205 mm

-

Reach - Ground Level2.67 ft 821 mm

-

Maximum Reach4.5 ft 1368 mm

-

Fork Depth Above Ground2 in 40 mm

-

Fork Height at Maximum Reach4.67 ft 1421 mm

-

Maximum Fork Height9.83 ft 3005 mm

-

Fork Reach at Maximum Height2 ft 600 mm

-

Turning Radius - Over Bucket*13.17 ft 4007 mm

-

Turning Radius - Inside Tire**5.92 ft 1816 mm

-

Width - Over Bucket*5.83 ft 1770 mm

-

Tire Gauge4.33 ft 1314 mm

-

Machine Width**5.58 ft 1708 mm

-

Articulation Angle40°

-

Steering Angle80°

-

Dump Angle at Maximum Height40°

-

Note (1)*Vary with bucket size.

-

Note (2)**Vary with tire size.

-

Note (3)Dimensions listed are based on the machine configured with cab with air conditioning, remote quick coupler, general purpose bucket or 1067 mm (42 in) forks, 75 kg (165 lb) operator, 33 × 15.5-16.5, 12 PR tires, without ride control, without precleaner.

Engine

-

Maximum Gross Power42 hp 31 kW

-

Engine ModelCat C2.4*

-

Gross Power42 hp 31 kW

-

Net Power - 2,200 rpm - SAE J1349 R-ing40 hp 30 kW

-

Net Power - 2,200 rpm - ISO 9249 R-ing40 hp 30 kW

-

Bore3.4 in 87 mm

-

Stroke4 in 102 mm

-

Displacement147 in² 2.4 l

-

Note*Engine meets U.S. EPA Tier 4 Final emission standards.

Hydraulic System

-

Main Relief3481 psi 240 bar

-

3rd Auxiliary Flow14 gpm 52 L/min

-

Hydraulic Cycle Time - Lower, Float2.4 s 2.4 s

Loader Hydraulic System

-

Hydraulic Cycle Time - Lift4.4 s 4.4 s

-

Hydraulic Cycle Time - Dump0.7 s 0.7 s

Maximum Material Densities - General Purpose

-

Bucket TypeGeneral Purpose

-

Rated Capacity0.8 yd³ 0.6 m³

-

Dump Height90 in 2290 mm

-

Maximum Material Density3169 lb/yd³ 1880 kg/m³

-

Bucket Width70 in 1770 mm

-

NoteBased on ISO 7546:1983 and rated operating loads at full turn and standard linkage.

Maximum Material Densities - Light Material

-

Bucket TypeLight Material

-

Rated Capacity1.3 yd³ 1 m³

-

Dump Height85 in 2160 mm

-

Maximum Material Density1989 lb/yd³ 1180 kg/m³

-

Bucket Width74 in 1880 mm

-

NoteBased on ISO 7546:1983 and rated operating loads at full turn and standard linkage.

Operating Specifications - High Lift

-

Tire Size33 × 15.5-16.5, 12 PR

-

Rated Bucket Capacity0.8 yd³ 0.6 m³

-

Breakout Force6204 lbf 28 kN

-

Operating Weight9462 lb 4292 kg

-

Rated Operating Load at Full Turn - Bucket***2502 lb 1135 kg

-

Straight Tipping Load - Bucket***5975 lb 2710 kg

-

Full Turn Static Tipping Load - Bucket (ISO 14397-1*)***5004 lb 2270 kg

-

Full Turn Static Tipping Load - Bucket (Rigid Tire**)***5115 lb 2320 kg

-

Rack Back - Transport Position51°

-

Rated Operating Load at Full Turn - Forks (EN 474-3:2006, Firm and Level Ground, 500 mm [20 in] Load Center) (80% FTSTL)***3148 lb 1428 kg

-

Rated Operating Load at Full Turn - Forks (EN 474-3:2006, Rough Terrain, 500 mm [20 in] Load Center) (60% FTSTL)***2361 lb 1071 kg

-

Note (1)*Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification be-tween calculation and testing.

-

Note (2)**Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

-

Note (3)***Manual quick coupler, precleaner hood.

-

Note (4)Operating specifications shown are based on machine equipped with enclosed ROPS cab with air conditioning, remote quick coupler, 75 kg (165 lb) operator and general purpose bucket (GP), without ride control, without precleaner unless otherwise noted.

Operating Specifications - Standard Lift

-

Tire Size33 × 15.5-16.5, 12 PR

-

Rated Bucket Capacity0.8 yd³ 0.6 m³

-

Breakout Force6160 lbf 27 kN

-

Operating Weight9414 lb 4270 kg

-

Rated Operating Load at Full Turn - Bucket***2701 lb 1225 kg

-

Straight Tipping Load - Bucket***6415 lb 2910 kg

-

Full Turn Static Tipping Load - Bucket (ISO 14397-1*)***5401 lb 2450 kg

-

Full Turn Static Tipping Load - Bucket (Rigid Tire**)***5512 lb 2500 kg

-

Rack Back - Transport Position51°

-

Rated Operating Load at Full Turn - Forks (EN 474-3:2006, Firm and Level Ground, 500 mm [20 in] Load Center) (80% FTSTL)***3366 lb 1527 kg

-

Rated Operating Load at Full Turn - Forks (EN 474-3:2006, Rough Terrain, 500 mm [20 in] Load Center) (60% FTSTL)***2524 lb 1145 kg

-

Note (1)*Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification be-tween calculation and testing.

-

Note (2)**Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

-

Note (3)***Manual quick coupler, precleaner hood.

-

Note (4)Operating specifications shown are based on machine equipped with enclosed ROPS cab with air conditioning, remote quick coupler, 75 kg (165 lb) operator and general purpose bucket (GP), without ride control, without precleaner unless otherwise noted.

Service Refill Capacities

-

Cooling System3 gal (US) 11 l

-

Fuel Tank11.4 gal (US) 43 l

-

Hydraulic System6.3 gal (US) 24 l

-

Engine Oil2.4 gal (US) 9 l

Sustainability

-

Recyclability97%

Transmission

-

Travel Speed12.4 mile/h 20 km/h

Weights

-

Operating Weight9414 lb 4270 kg

Benefits

Work Made Easy

The 903D Makes Work Easy with a 25% increase in tipping capacity to handle classic landscaping materials along with a 25% faster ground speed. The optional hydraulic Skid Steer Loader style coupler allows for changing work tools without getting out of the cab. Optional front and rear diff-lock can be activated on the fly, providing maximum traction in slick underfoot conditions.

Enjoy All Day Comfort

Operators will Enjoy All Day comfort with a new multi-function joystick, increased leg room, improved pedal positioning, easier entry/exit and optional speed sensitive ride control. The minimal engine overhang provides excellent rear and corner visibility, making the 903D easy to operate in confined areas.

Configured for Success

Configure the 903D for success with new options such as engine and ground speed control, ideally suited for hydro-mechanical work such as using a broom. With the addition of a Worktool Electrical Harness option, you can now run more tools than ever before. Two loader linkage options, standard and high lift, provide either improved capacity or improved lift height based on your application.

Simply Reliable

Fully opening rear hood allows easy access to the engine compartment featuring side-by-side coolers and transparent fuel/water separator with optional engine air precleaner and radiator screen for high debris applications. New rear tie down locations under the machine allow for easier transport, while a new engine oil fill location allows for easier access during engine oil changes.

Equipment Info

POWER TRAIN

Air cleaner, two stage with visual indicator

ELECTRICAL

12 volt direct electric starting

OPERATOR ENVIRONMENT

Cup holder

OTHER STANDARD EQUIPMENT

3rd valve auxiliary hydraulics with continuous flow detent, standard flow

Product Brochures