Conditional Content 1

Conditional Content 2

D9

D9

Over 310 hp, Caterpillar's large Dozers are engineered for demanding work. Durable construction is ensured for tough working conditions. Elevated sprockets increase productivity, simplify maintenance, reduce downtime with modular components and raise final drives and associated power train components out of the work environment. Cat® Mining Dozers keep material moving with the reliability and low operating costs expected from Cat tractors.

Book a Demo

Explore my deals

Specifications

Air Conditioning System

-

Air ConditioningThe air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430) the system contains 2.1 kg of refrigerant which has a CO2 equivalent of 3.003 metric tonnes.

Blade - Semi-Universal

-

Blade Capacity (SAE J1265)17.8 yd³ 13.6 m³

-

Blade Width (over end bits)171.3 in 4350 mm

-

Blade Height76.1 in 1934 mm

-

Maximum Digging Depth23.9 in 606 mm

-

Ground Clearance at Full Lift56 in 1422 mm

-

Maximum Tilt37 in 940 mm

-

Blade Weight10587 lb 4802 kg

-

Total Operating Weight* (with blade and single-shank ripper)110205 lb 49988 kg

-

Note* Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type.

Blade - Universal

-

Blade Capacity (SAE J1265)21.7 yd³ 16.6 m³

-

Blade Width (over end bits)184.3 in 4680 mm

-

Blade Height76.1 in 1934 mm

-

Maximum Digging Depth23.9 in 606 mm

-

Ground Clearance at Full Lift56 in 1422 mm

-

Maximum Tilt39.9 in 1014 mm

-

Blade Weight12016 lb 5450 kg

-

Total Operating Weight* (with blade and single-shank ripper)111362 lb 50513 kg

-

Note*Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type.

Dimensions (Approximate)

-

Ground Clearance*18.1 in 459 mm

-

Track Gauge88.6 in 2250 mm

-

Width - Without Trunnions - Standard Shoe113 in 2870 mm

-

Width - Over Trunnions130.3 in 3310 mm

-

Height - FOPS Cab*150.4 in 3820 mm

-

Height - Top of Stack*152.6 in 3876 mm

-

Height - ROPS/Canopy*157.5 in 4000 mm

-

Drawbar Height (Center of Clevis)*30 in 763 mm

-

Length - Track on Ground136.6 in 3470 mm

-

Overall Length - Basic Tractor193.3 in 4910 mm

-

Length - Basic Tractor - With Drawbar206.4 in 5242 mm

-

Length - Basic Tractor - With Winch218.3 in 5545 mm

-

Length - With SU-Blade**259.9 in 6601 mm

-

Length - With U-Blade274.3 in 6967 mm

-

Length - With Single-Shank Ripper257 in 6529 mm

-

Length - With Multi-Shank Ripper257.4 in 6538 mm

-

Overall Length - SU-Blade/SS Ripper323.6 in 8219 mm

-

Note (1)*Includes grouser height for total dimensions on hard surfaces.

Engine - U.S. EPA Tier 2/3 Equivalent

-

Engine ModelCat® C18

-

Engine Power - Net SAE J1349/ISO 9249452 hp 337 kW

-

Bore5.7 in³ 145 mm

-

Stroke7.2 in 183 mm

-

Displacement1106 in³ 18.1 l

-

Engine Power - Gross SAE J1995487 hp 363 kW

-

Engine Power - ISO 14396479 hp 357 kW

-

EmissionsU.S. EPA Tier 2 or Tier 3 equivalent

-

Note (1)All engine ratings apply at 1,750 rpm.

-

Note (2)No derating required up to 4267 m (14,000 ft) altitude.

Engine - U.S. EPA Tier 4 Final/EU Stage V

-

Engine ModelCat® C18

-

Bore5.7 in³ 145 mm

-

Stroke7.2 in³ 183 mm

-

Displacement1106 in³ 18.1 l

-

Engine Power - Gross SAE J1995477 hp 356 kW

-

Engine Power - ISO 14396468 hp 349 kW

-

Engine Power - Net SAE J1349/ISO 9249440 hp 328 kW

-

EmissionsU.S. EPA Tier 4 / EU Stage V

-

Note (1)All Engine ratings apply at 1,750 rpm.

-

Note (2)No derating required up to 2499 m (8,200 ft).

FLUID CAPACITIES

-

Fuel Tank (Splash Fill)254 gal (US) 963 l

-

DEF Tank (Tier 4 only)9.5 gal (US) 36 l

-

Fuel Tank (Fast Fill)248 gal (US) 939 l

-

Cooling System21 gal (US) 81.3 l

-

Engine Crankcase*10 gal (US) 36 l

-

Powertrain40 gal (US) 150 l

-

Final Drives (each)4 gal (US) 15 l

-

Roller Frames (each)12 gal (US) 45 l

-

Pivot Shaft Oil8 gal (US) 30 l

-

Hydraulic System Tank24 gal (US) 89 l

-

Note*With oil filters.

-

Note 2Biodiesel blends up to B20 (20% blend by volume) are acceptable when blended with 15 ppm (mg/kg) sulfur or less ULSD. B20 should meet ASTM D7467 specification (biodiesel blend stock should meet Cat biodiesel spec, ASTM D6751 or EN 14214). Cat DEO-ULSTM or oils that meet the Cat ECF-3, API CJ-4, and ACEA E9 specification are required. Consult your OMM for further machine specific fuel recommendations.

-

Note 3All non-road Tier 4 Final diesel engines are required to use only ultra-low sulfur diesel (ULSD) fuels containing 15 ppm (mg/kg) sulfur or less.

-

Note 4Diesel Exhaust Fluid (DEF) used in Cat Selective Catalytic Reduction (SCR) systems must meet the requirements outlined in the International Organization for Standardization (ISO) standard 22241.

Hydraulic Controls

-

Pump TypePiston-type geared to flywheel

-

Pump Output - Steering96 gal/min 363 l/min

-

Fan Pump21 gal/min 80 l/min

-

Tilt Cylinder Flow - Rod End Flow53 gal/min 200 l/min

-

Tilt Cylinder Flow - Head End Flow53 gal/min 200 l/min

-

Lift Cylinder Relief Valve Setting3800 lbf/in 26200 kPa

-

Tilt Cylinder Relief Valve Setting2799 psi 19300 kPa

-

Ripper - Lift - Relief Valve Setting3800 psi 26200 kPa

-

Ripper - Pitch - Relief Valve Setting3800 psi 26200 kPa

-

Steering System - Pressure5874 psi 40500 kPa

-

Tank Capacity24 gal/min 89 l

-

Note (1)Steering pump output measured at 1,750 engine rpm and 30 000 kPa (4,350 psi).

-

Note (2)Implement pump output measured at 1,750 engine rpm and 20 000 kPa (2,900 psi).

-

Note (3)Fan pump output measured at 1,750 engine rpm and 17 000 kPa (2,470 psi)

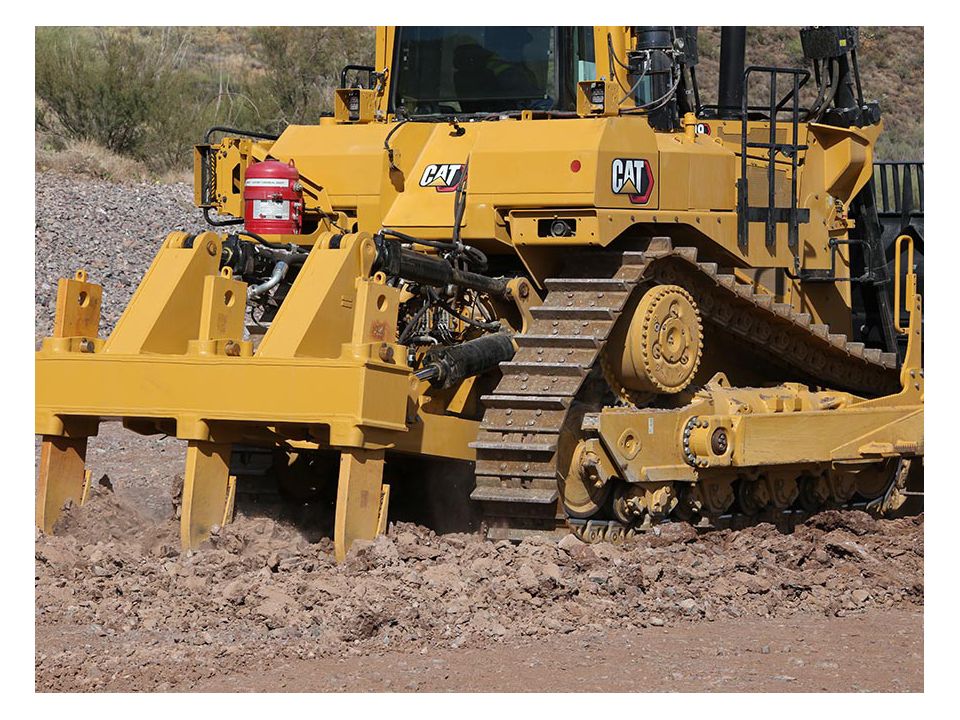

Ripper - Multi-Shank, Adjustable Parallelogram

-

Maximum Penetration Force - Shank Vertical34621 lbf 154 kN

-

Maximum Penetration - Standard Tip31.4 in 798 mm

-

Pry-Out Force - Multi-Shank Ripper with One Tooth81156 lbf 361 kN

-

Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole34.6 in 879 mm

-

Number of Pockets3

-

Weight12136 lb 5550 kg

-

Total Operating Weight* - With SU-Blade and Ripper111739 lb 50684 kg

-

Note* Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type.

Ripper - Single Shank

-

Maximum penetration force * (shank vertical)35520 lbf 158 kN

-

Maximum penetration depth (standard tip)48.5 in 1231 mm

-

Pryout Force74637 lbf 332 kN

-

Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole34.7 in 882 mm

-

Number of Pockets1

-

Weight10701 lb 4854 kg

-

Total Operating Weight* (with SU Blade and noted ripper)110205 lb 49988 kg

-

Note*Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type.

Ripper - Single Shank, Deep Ripping

-

Maximum penetration force * (shank vertical)38667 lbf 172 kN

-

Maximum penetration depth (standard tip)68 in 1727 mm

-

Pryout Force74412 lbf 331 kN

-

Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole32.2 in 817 mm

-

Number of Pockets1

-

Weight10981 lb 4981 kg

-

Total Operating Weight* (with SU Blade and noted ripper)110485 lb 50115 kg

-

Note*Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type.

Standards

-

ROPSRollover Protective Structure (ROPS) meets the following criteria ISO 3471:2008.

-

FOPSFalling Object Protective Structure (FOPS) meets the following criteria ISO 3449:2005 LEVEL II.

-

SoundThe average dynamic spectator sound power level when ISO 6395:2008 is used to measure the value for a machine is 116 dB(A). The measurement was conducted at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds. NOTE: The dynamic sound power level uncertainty is +/-2 dB(A).

-

Sound (1)The average dynamic operator sound pressure level when ISO 6396:2008 is used to measure the value for an enclosed cab is 78 dB(A). The measurement was conducted at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds. The cab was properly installed and maintained. The measurement was conducted with the cab doors and the cab windows closed. NOTE: The dynamic operator sound pressure level uncertainty is +/-2 dB(A).

-

Sound (2)Hearing protection may be needed when the machine is operated with an open operator station for extended periods, in a noisy environment, or with a cab that is not properly maintained.

Steering and Brakes

-

Steering TypeDifferential

-

Brake TypeSpring Applied Wet Disc

-

Brake Diameter15.5 in 393.7 mm

-

Brake Count8

Transmission

-

1.0 Forward2.2 mile/h 3.5 km/h

-

2.0 Forward3.9 mile/h 6.3 km/h

-

3.0 Forward6.8 mile/h 11 km/h

-

1.0 Reverse2.7 mile/h 4.4 km/h

-

2.0 Reverse4.8 mile/h 7.8 km/h

-

3.0 Reverse8.4 mile/h 13.6 km/h

-

TypePlanetary powershift

Undercarriage

-

Shoe TypeExtreme Service

-

Width - Shoe24 in 610 mm

-

Shoes/Side43

-

Grouser Height3.3 in 84 mm

-

Pitch9.4 in 240 mm

-

Ground Clearance18.1 in 459 mm

-

Track Gauge88.6 in 2250 mm

-

Length - Track on Ground136.6 in 3470 mm

-

Ground Contact Area45.6 ft² 4.23 m²

-

Track Rollers/Side8

-

Number of Carrier Rollers1 per side (optional)

Weights

-

Operating Weight110225 lb 49988 kg

-

Shipping Weight84373 lb 38271 kg

-

Note (1)D9 Operation Weight includes hydraulic controls, blade tilt cylinder, coolant, lubricants, full fuel tank, ROPS, FOPS cab, SU Blade, Single-Shank Ripper, 610 mm (24 in) ES shoes and operator.

-

Note (2)D9 Operation Weight includes base machine chassis with cab, pivot shaft, roller frames, track and ROPS.

Winches

-

Winch ModelPA 140VS

-

Weight*3950 lb 1790 kg

-

Oil Capacity4 gal (US) 15 l

-

Drum Width12.6 in 320 mm

-

Wire Cable Diameter - Recommended1.13 in 28 mm

-

Wire Cable Diameter - Optional1.25 ft 32 mm

-

Maximum Drum Capacity - Recommended Cable Length257 in 78 m

-

Maximum Drum Capacity - Optional Cable Length204 ft 62 m

-

Wire Cable Ferrule Size - Outside Diameter2.4 in 60 mm

-

Wire Cable Ferrule Size - Length2.8 in 70 mm

-

Note*Weight shown is base winch only. Does not include mounting arrangement, control arrangement, oil, or wire rope. With counterweight: 3700 kg (8,150 lb).

-

Note (2)Variable speed, hydraulically driven, dual braking system, three-roller fairlead.

Benefits

PERFORMANCE & EFFICIENCY

- The torque converter with stator clutch automatically frees up the stator when torque multiplication is not required under low load, resulting in higher drivetrain efficiency for reduced fuel consumption.

- Bogie suspension allows the track to conform to ground conditions, delivering higher traction and less slippage.

- Differential steering enables large loads, with fast and smooth maneuvering.

OPERATOR COMFORT

- The cab is unparalleled, with enhanced ergonomics, a fully adjustable air suspension seat and automatic temperature control.

- The suspended undercarriage absorbs impact and reduces shock loads transferred to the undercarriage by up to 50% for a smoother, more comfortable ride.

- Low-effort electronic steering, ripper and dozer controls are easily accessible and provide sure, precise maneuvering.

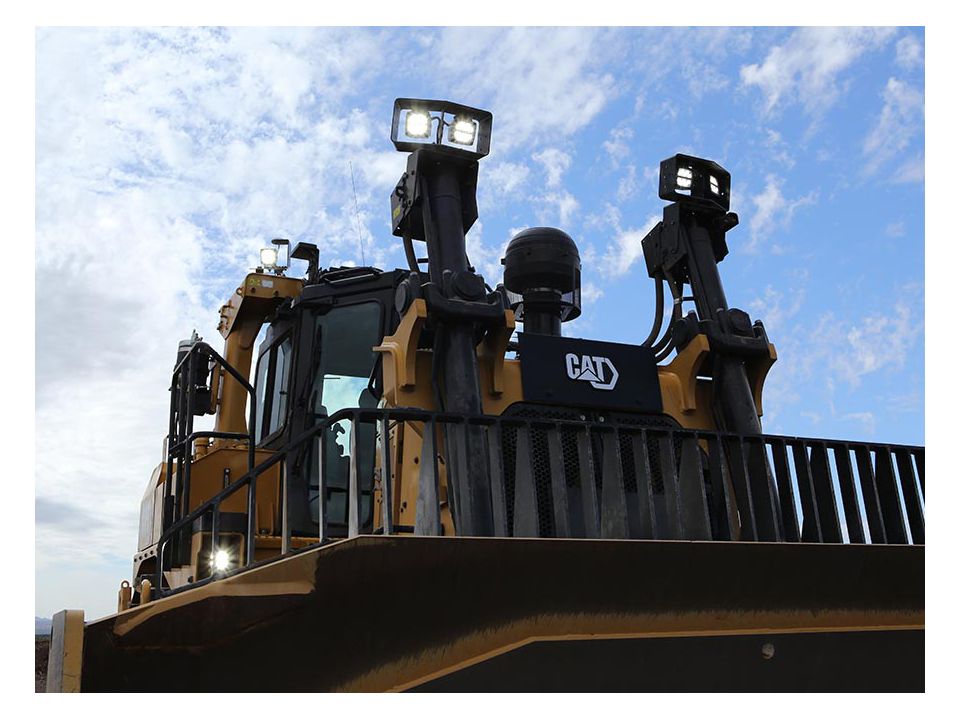

SAFETY

- The operator station offers an exceptional viewing area, with a tapered hood, notched fuel tank, and narrow ripper carriage to give the operator a clear line of sight to front and rear work areas.

- The optional 360 Vision camera system and in-cab display further enhance visibility.

- An optional powered ladder improves access and egress.

- Ground-level access, forward-hinging cab door, retention pins on bottom guard and removed lift cylinder grease points provide a greater level of safety for service personnel.

PRODUCTIVITY

- Differential steering provides a tight turning radius and maintains a high ground speed while turning.

- The planetary powershift transmission controls permit smooth speed and direction changes with Advanced Productivity Electronic Control System (APECS).

- The in-cab touchscreen Information Display is larger, faster, and more powerful with increased memory and intuitive menu structure.

- The optional Work Monitor screen collects machine data and provides real-time feedback on machine performance to optimize productivity.

- The Dual Tilt option allows the operator to optimize blade pitch angle, improving load control and making it possible to carry material instead of only pushing it.

VERSATILITY

- The D9 is versatile enough for a variety of applications and is ideal for use in heavy construction, quarries, landfills, stockpiles, forestry and mine sites.

- The powerful Cat C18 Engine is available in U.S. EPA Tier 2, U.S. EPA Tier 3, U.S. EPA Tier 4 Final and EU Stage V configurations.

- The fully suspended undercarriage provides more ground contact, leading to less slippage and more overall productivity in all applications.

- Continuous power to both tracks provides smooth turning control and excellent maneuverability in every application, all while keeping ground speed high.

TECHNOLOGY & INNOVATION

- Product Link™ Elite enables the remote transmission of information about the location, operation and condition of your equipment.

- Automated Blade Assist (ABA) (optional) increases efficiency while reducing operator workload, making use of preset blade pitch positions for the load, carry and spread portions of the cycle.

- AutoCarry™ (optional) automates blade lift to maintain desired blade load, improve load consistency and reduce track slip.

- Automatic Ripper Control (optional) automatically controls ripper height to limit track slip, reducing operator fatigue.

- Optional Cat MineStar™ Command for dozing offers multiple levels of remote-control operation.

SERVICEABILITY

- Features such as integrated AutoLube System, fewer greasing points, longer filter change intervals, easy component removal and continuous fluid level monitoring contribute to up to 4% maintenance and repair savings.

- Grouped maintenance points minimize movement around the machine, and ground-level access enables easier service for fluids and key electrical controls.

- Remote flash sends an alert from your Cat dealer, prompting you to update the software on your machine. Updates can be deployed on site, without having to wait for a dealer technician to arrive.

BLADES & ATTACHMENTS

- The perfect match for the D9, Cat blades are aggressive in tough materials and offer superior loadability.

- Cat blades have the ability to resist torsional bending and distortion and offer increased wear resistance without sacrificing machine balance or performance.

- Specialty attachments include single-shank ripper and multi-shank ripper

BUILT TO GO THE DISTANCE

- Frame is built to absorb high-impact shock loads and twisting forces encountered during severe dozing and ripping applications.

- Powertrain and main components are built to be rebuilt for a cost-effective second life of like-new performance at a fraction-of-new price.

- The DuraLink™ undercarriage offers 20 to 40% longer life and delivers 8,000-hour seal life with new, heavy-duty extended-life (HDXL) undercarriage.

SUSTAINABILITY

- The D9 is designed to use less fuel, which reduces engine emissions.

- The Tier 4 Final engine reduces NOx and particulate matter, plus the engine is compatible with diesel fuel blended with lower-carbon intensity fuels such as biofuels and renewable fuels.

- Features like extended life filters and longer maintenance intervals decrease the amount of waste contributed to the environment.

- By rebuilding machines and components, the Cat Rebuild and Cat Reman programs preserve raw materials, conserve energy and reduce emissions. In addition, retrofits and upgrades for older machines incorporate efficiency improvements and emission reductions, and keep them in production longer to conserve energy and minimize the need for raw materials.

- Increased commonality of systems and components, plus a reduction in unique part numbers, reduces waste and lowers owning and operating costs.

Equipment Info

OPERATOR ENVIRONMENT

ROPS/FOPS, Sound-Suppressed Cab

TECHNOLOGY

VIMS™

POWER TRAIN

Aftercooler, air-to-air

FLUIDS

Coolant — Extended Life, Standard (— 37° C / — 25° F)

UNDERCARRIAGE

Suspension-Type Undercarriage

HYDRAULICS

Electronically Controlled, Load-Sensing Dozer Lift and Tilt

ELECTRICAL

Alternator — 150-Amp

SERVICE AND MAINTENANCE

Ecology Fluid Drains — All Compartments

Product Brochures