D2

D2

The Cat® small dozers are designed to optimize speed, transportability, maneuverability, versatility and finish grading accuracy. These crawler dozers are ideal for residential construction performing such tasks as clearing and grading lots, sloping the sides of roads, back-filling, and final grade work for landscaping and driveway construction.

Book a Demo

Explore my deals

Specifications

Air Conditioning System

-

Air ConditioningThe air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf (Europe). See label or instruction manual for gas refrigerant identification. If machine is equipped with R134a (Global Warming Potential = 1430), the system contains 1.8 kg (4.0 lbs) of refrigerant, which has a CO2 equivalent of 2.574 metric tonnes (2.873 tons). If machine is equipped with R1234yf (Global Warming Potential = 0.501), the system contains 1.7 kg (3.75 lbs) of refrigerant, which has a CO2 equivalent of less than 0.001 metric tonnes (0.001 tons).

Cab

-

FOPSISO 3449:2005 Level II

-

ROPSISO 3471:2008

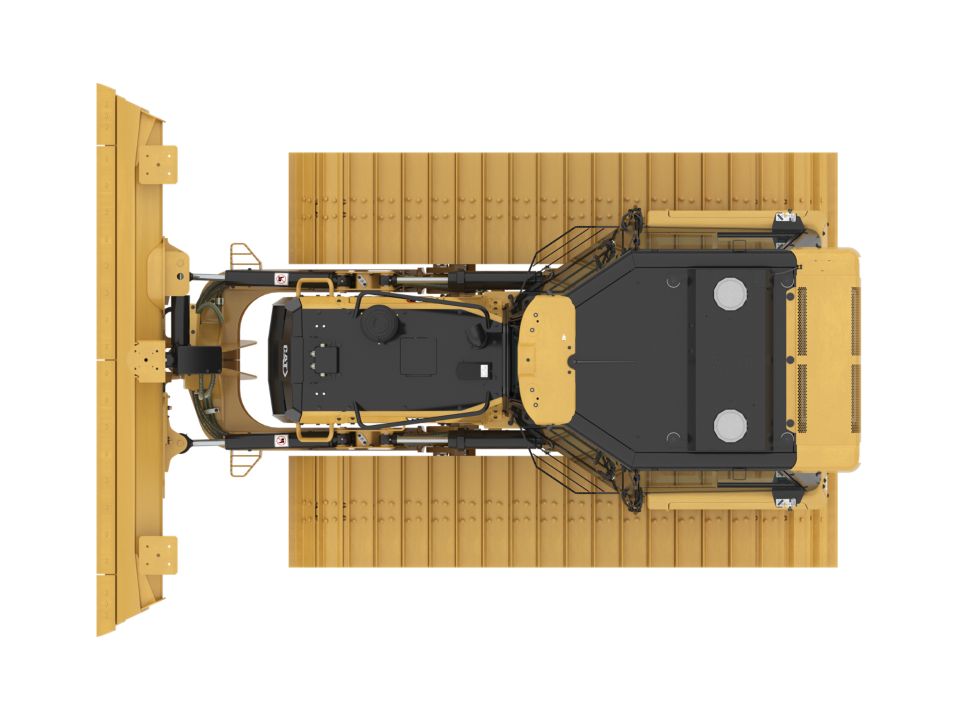

Dimensions

-

BLADE: Digging Depth - LGP23.2 in 589 mm

-

BLADE: Blade Cutting Edge Angle, Adjustable - LGP52° to 58°

-

BLADE: Blade Lift Height - LGP27.9 in 708 mm

-

BLADE: Blade Width - LGP124 in 3149 mm

-

BLADE: Blade Width at Maximum Angle - LGP113.1 in 2874 mm

-

Track Gauge - LGP67.9 in 1725 mm

-

Ground Clearance - LGP13 in 332 mm

-

BLADE: Blade Height - LGP35.8 in 910 mm

-

Overall Length - With Blade - LGP168.2 in 4272 mm

-

BLADE: Blade Capacity (SAE) - LGP2.42 yd³ 1.85 m³

-

BLADE: Maximum Tilt - LGP17.2 in 438 mm

-

BLADE: Maximum Angle (either side) - LGP25°

-

NoteAbrasion Undercarriage

-

Length of Basic Dozer (without blade) - LGP129.5 in 3290 mm

-

Width of Dozer (standard shoes, no blade) - Standard79.1 in 2010 mm

-

Dozer Height - LGP108.9 in 2765 mm

-

Dozer Height - Standard108.9 in 2765 mm

-

Width of Dozer (standard shoes, no blade) - LGP92.9 in 2360 mm

-

Length of Basic Dozer (without blade) - Standard129.5 in 3290 mm

Dimensions

-

BLADE: Maximum Angle (either side) - Standard25°

-

Ground Clearance - Standard13 in 332 mm

-

Overall Length - With Blade - Standard168.5 in 4281 mm

-

BLADE: Blade Cutting Edge Angle, Adjustable - Standard52° to 58°

-

BLADE: Maximum Tilt - Standard15.2 in 387 mm

-

Track Gauge - Standard61 in 1550 mm

-

BLADE: Digging Depth - Standard23.3 in 593 mm

-

BLADE: Blade Width - Standard109.5 in 2782 mm

-

BLADE: Blade Lift Height - Standard29.3 in 743 mm

-

BLADE: Blade Capacity (SAE) - Standard2.59 yd³ 1.98 m³

-

BLADE: Blade Width at Maximum Angle - Standard100.1 in 2542 mm

-

NoteWith Ripper Attachment (add to Length of Basic Dozer) - 1177 mm (46.3 in)

-

BLADE: Blade Height - Standard39.8 in 1010 mm

Engine

-

Engine ModelCat® C3.6

-

Power - Net92 hp 68.8 kW

-

Displacement220 in³ 3.6 l

-

Net Power - 2,200 rpm - SAE J134992 hp 68.8 kW

-

Net Power - 2,200 rpm - ISO 9249/EEC 80/126992 hp 68.8 kW

-

Note (1)Net power is tested per ISO 9249:2007 and SAE J1349:2011 and as advertised is the power available at the ?ywheel when the engine is equipped with fan, air intake system, exhaust system and alternator.

-

Note (2)All non-road U.S. EPA Tier 4 Final, EU Stage V, Japan 2014 (Tier 4 Final) and Korea Tier 4 Final diesel engines are required to use only Ultra Low Sulfur Diesel (ULSD) fuels containing 15 ppm EPA/10 ppm EU (mg/kg) sulfur or less.

Engine

-

Power TrainHydrostatic

High Performance Winch

-

Maximum line pull – bare drum40000 lb 18144 kg

-

Drum capacity – recommended cable371 ft 113 m

-

Winch length27.76 in 705 mm

-

Overall width29.2 in 741 mm

-

ControlHydraulic

-

Maximum line speed – bare drum131 ft/min 40 m/min

-

Maximum line speed – full drum207 ft/min 63 m/min

-

Drum width10.8 in 274 mm

-

Drum capacity – optional256 ft 78 m

-

Throat clearance6.75 in 171.5 mm

-

Weight1345 lb 610 kg

-

Rope diameter – recommended0.63 in 16 mm

-

SpeedVariable

-

Maximum line pull – full drum25000 lb 11340 kg

-

Drum diameter10 in 254 mm

-

Rope diameter – optional0.75 in 19 mm

-

Winch driveHydrostatic

Hydraulic Controls

-

Pump Output17.2 gpm 65 L/min

-

Relief Valve Settings2988 psi 20600 kPa

Retrieval Winch

-

Maximum Line Speed - Full Drum79 ft/min 24 m/min

-

Maximum Line Speed - Bare Drum50 ft/min 15 m/min

-

Weight1747 lb 794 kg

-

Drum Capacity - Optional Cable195 ft 59 m

-

Rope Diameter - Recommended0.63 in 16 mm

-

Winch DriveHydraulic

-

Rope Diameter - Optional0.75 in 19 mm

-

Drum Capacity - Recommended Cable277 ft 84 m

-

Maximum Line Pull - Full Drum20350 lb 9231 kg

-

SpeedVariable

-

Maximum Line Pull - Bare Drum32150 lb 14583 kg

-

ControlHydraulic

-

Overall width27.91 in 709 mm

-

Drum Width9.65 in 245 mm

-

Drum Diameter8 in 203.2 mm

-

Winch Length35.63 in 905 mm

-

Throat Clearance5.6 in 141.4 mm

Ripper

-

TypeParallelogram

-

Number of Shanks3

-

Height6.5 in 165 mm

-

Weight1222 lb 554 kg

-

Maximum Digging Depth13.3 in 337.5 mm

-

Maximum Ground Clearance Under Tip17.6 in 448 mm

-

Overall Width67.3 in 1710 mm

-

Maximum Reach - Ground Line30.2 in 766 mm

Service Refill Capacities

-

Fuel Tank51.5 gal (US) 195 l

-

Crankcase - With Filter2.8 gal (US) 10.5 l

-

Final Drive - Each - LGP2.6 gal (US) 10 l

-

Cooling System5 gal (US) 19 l

-

Transmission - Hydraulic Tank23.8 gal (US) 90 l

-

Diesel Exhaust Fluid (DEF) Tank4.9 gal (US) 19 l

Service Refill Capacities

-

Final Drives - Each Side2.6 gal (US) 10 l

Transmission

-

Drive Pumps1

-

Maximum Travel Speed - Forward5.6 mile/h 9 km/h

-

Relief Valve Settings7033 psi 48500 kPa

-

Maximum Travel Speed - Reverse6.2 mile/h 10 km/h

-

Track Motors2

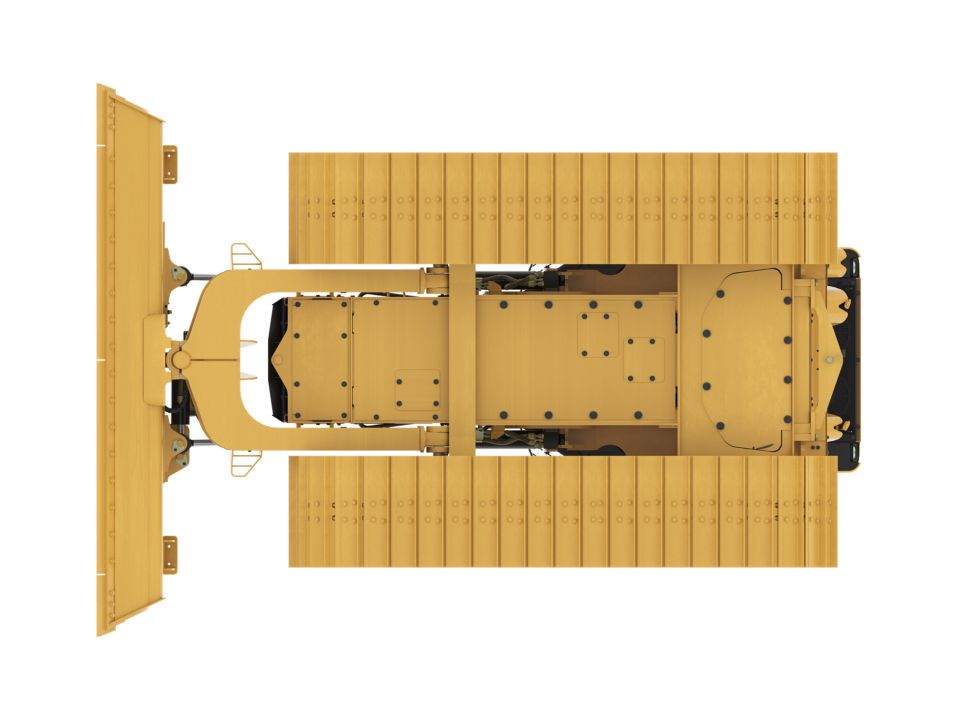

Undercarriage

-

Length - Track on Ground - LGP89 in 2248 mm

-

Track Gauge61 in 1550 mm

-

Number of Rollers - Each Side7

-

Track Gauge - LGP68 in 1725 mm

-

Ground Pressure - LGP4.3 psi 29.7 kPa

-

Shoe Width - Standard18 in 460 mm

-

Shoe Width - LGP25 in 635 mm

-

Number of Shoes - Each Side - Sealed and Lubricated Track (SALT) Undercarriage43

Undercarriage

-

Number of Shoes - Each Side - Abrasion Undercarriage38

-

Ground Pressure5.7 psi 39.5 kPa

-

Length of Track on Ground89 in 2248 mm

Weights

-

Operating Weight18382 lb 8338 kg

-

Operating Weight18382 lb 8338 kg

-

Operating Weight - LGP19066 lb 8648 kg

-

Note (2)For machine with ripper, add 554 kg (1,222 lb).

-

Note (1)Specifications shown are for machine equipped with dozer blade, EROPS cab, back-up alarm, operator, coolant, lubricants and full fuel tank.

Benefits

IMPROVED VISIBILITY

- The sloped hood provides better visibility to the work in front of the blade as well as the overall job site. Better visibility can equal less operator fatigue and more confidence in your work.

ENHANCED TECHNOLOGY

Cat small dozers include a suite of Operator Assist features that work seemlessly to save time, effort, fuel, machine wear and overall costs. Cat Grade with Assist is an optional technology available for small dozers.

- Steer Assist automates track steering with light or heavy loads and automates blade tilt steering to help push heavy loads with less effort. This feature helps reduce operator inputs by up to 75% and enhances operator efficiency and productivity. Steer Assist is standard with Assist with Attachment Ready Option (ARO). Steer Assist 3D is standard with Grade 3D with Assist.

- Stable Blade Lift and Tilt automatically works behind the scenes to allow operators to create smooth surfaces with less effort using accelerometers on the blade and chassis with an advanced algorithm to make minor blade raise and lower movements. Stable Blade Lift and Tilt is standard with Assist with ARO and Grade 3D with Assist.

- Blade Load Monitor provides real-time feedback of current load vs. target load to fully utilize machine capacity benefiting operators of all skills levels. Automatically compensates for ground conditions. This feature is not available indoors or in areas where a GPS signal is not available. Blade Load Monitor is standard with Assist with ARO and Grade 3D with Assist.

- Low Slip Traction Control prevents excessive track slip to improve machine efficiency and reduce burden on the operator. Feature offers two modes: Normal Mode helps when pushing heavy blade loads by limiting non-productive track slip, recommended for most applications. And Low Slip Mode limits track slip for applications sensitive to slip such as spreading material on top of a liner, select this mode when needed. Traction Control is standard with Assist with ARO and Grade 3D with Assist

- AutoCarry™ raises and lowers the blade to maximize pushing capability and prevent excessive track slip when pushing heavy loads. Feature is designed to work in unison with other Operator Assist Features. Not available indoors or in areas where a GPS signal is not available. AutoCarry is standard with Assist with ARO and Grade 3D with Assist.

- Scalable Grade 2D and 3D with Assist is an optional feature that makes your job up to 39% faster with up to 82% fewer operator inputs and less rework by maintaining blade angles for better surface quality – even with less experienced operators.

- Cat Command remote control is an optional feature that takes you off the machine and away from hazardous conditions, dust, noise or vibration or operating on unstable surfaces. Eliminates risk of injury from climbing on or off the machine. Integrated with dozer systems, Cat Command enables smooth, precise control with access to all machine functions and advanced features (if equipped) for maximum efficiency and productivity. Availability varies by region.

UP TO 10% IMPROVED FUEL ECONOMY

- The D2 features the lowest fuel consumption in this size class with the same great performance you've come to expect. Up to 20% improvement and no performance sacri?ce when ECO mode is active.

COMFORTABLE WORK SPACE

- The spacious and comfortable cab features an optional heated and ventilated seat, along with heated joystick controls to make the operator comfortable no matter what the conditions are outside. The seat height and armrests can be easily adjusted to the operator’s preference.

BIGGER, BETTER DISPLAY WITH CAMERA

- This new and improved optional 10 in (254 mm) touchscreen, color display is easy to use, with a great view of machine settings, rearview camera and Slope Indicate/Slope Assist screens. The large reversing camera gives the operator better visibility to the job site.

DURABLE UNDERCARRIAGE

- The D2 is available with either a Heavy Duty (HD) or Abrasion undercarriage to best suit your application. The undercarriage has a longer life resulting in less down time. A one piece mainframe/track roller frame design and the large, double reduction planetary final drive allow the machine to push heavy loads.

SUSTAINABILITY

- The Cat® C3.6 engine meets U.S. EPA Tier 4 Final, EU Stage V, Japan 2014, and Korea Tier 5 emission standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) * or 100% renewable diesel, HVO (hydrogenated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Auto Engine Speed Control helps reduce unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- Cat® Grade with Slope Assist™ helps you avoid costly rework and wasteful fuel burn and greenhouse gas emissions by automating your blade position without a GPS signal.

- Cat® Grade with 3D automates blade movements using a GPS signal helping you follow a grade design, reducing fuel burn and greenhouse gas emissions by improving efficiency and accuracy.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- VisionLink® displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range.

- Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

- Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency by allowing your Cat dealer to virtually test the machine while working. Once a problem is identified, a technician can fix it the first time, saving time and money.

Equipment Info

POWER TRAIN

Air cleaner with precleaner, automatic dust ejection and under hood intake

ELECTRICAL

Alarm, backup

UNDERCARRIAGE

Heavy Duty (HD) Undercarriage (43 section)

HYDRAULIC

Hydraulic pump and oil

CAT TECHNOLOGY

Low Slip Traction Control (included with ARO and Cat Grade 3D)

ATTACHMENTS

Rigid drawbar

OPERATOR ENVIRONMENT

Armrests, adjustable