Conditional Content 1

Conditional Content 2

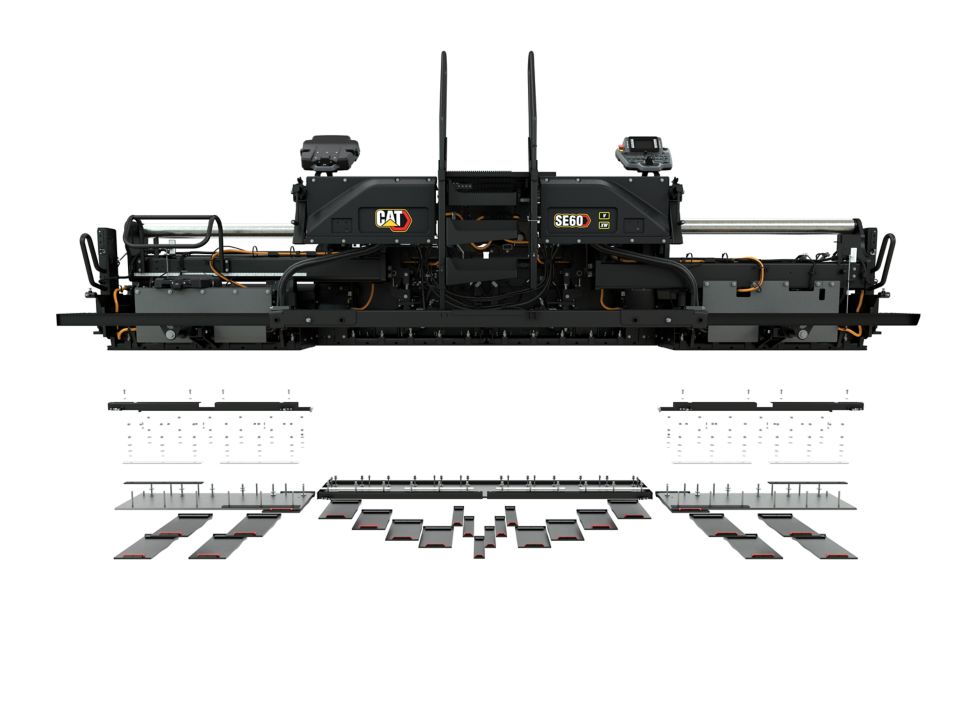

Cat® SDX Screed Plate System

Cat® SDX Screed Plate System

Cat® Screeds can be configured to match any paving application - from highways to city streets to parking lots. Even when set up for maximum paving width, Cat Screeds resist flexing due to unique, robust guide tube design. Select front-mount or rear-mount hydraulic screed extensions, both with optional power-extending main frames.Caterpillar has a full line of vibratory and tamper bar screeds to cover all paving widths while producing high density layers on asphalt as well as other granular materials. User-friendly controls simplify tamper setup and vibrating frequencies to match production rate, paving depth and paving speed. Operators can easily adjust the ramp time for tamping speed.Cat Screeds are simple to set up for consistently smooth transverse joints and minimum screed plate wear. Heavy-duty frames on both 2.5 m (8.0') and 3.0 m (10') screeds allow installation of bolt-on screed extensions for extra-wide paving.

Book a Demo

Explore my deals

Specifications

Dimensions

-

Paving Range with SE50 V2.55 m - 6.50 m (8' 4" – 21' 4")

-

Paving Range with SE60 V3 m to 7.45 m (9' 10" - 24' 5")

-

Paving Range with SE60 V XW3 m to 7.95 m (9' 10" - 29' 4")

Operating Specifications

-

Heating SystemElectric

Benefits

Increased Density and Smoothness

Two Plate Designs Available

- The system offers two extended-life plate designs that provide flexibility for highways, interstates, and commercial paving applications.

- The textured plates are designed to increase density and smoothness, while the smooth plates perform like traditional flat screed plate designs with the added benefit of modular, quick-change capability.

- In testing performed by Caterpillar utilizing ASTM G65 Dry Sand Rubber Wheel test procedures, the chromium-alloy material utilized in Cat SDX extended-life screed plates provided 4.2X more abrasion resistance when compared to the material utilized in standard-wear Cat screed plates. Note: Test results do not guarantee similar abrasion resistance improvements in paving application performance. Results may vary due to individual plate variation, paving techniques, and paving conditions.

Faster Screed Plate Changes

- Hardware-free screed plate installation saves time and effort

- Tapered blocks integrated into the screed plates fit over the beveled edge of the adapter plates and are held in place with high-temperature silicone retainers that maintain tension for reliable performance

- One-time adapter plate install attaches to the screed frame utilizing the existing screed plate orientation

- Heating elements attach to the adapter plates

- Modular screed plates come in 300 mm (12”) sections that weigh approximately 16 kg (35 lbs.). The plates are interchangeable across the screed width to help maximize wear.

- The center screed section consists of 100 mm (4”) plates that weigh approximately 5 kg (12 lbs.). These narrow plates allow for crown at the center of the screed.

Innovative Material Flow

- The angular surface provides a kneading action as mix passes through the diamond-shaped grooves and the tapering flat surface at the back of the plates provide a smooth finished surface

- Confined mixing action manipulates aggregates to reduce air voids and increase density while creating a uniform surface texture

- Optimized aggregate structure promotes surface temperature uniformity for consistent compaction

- Enhanced structural integrity minimizes roller shoving for better smoothness

- Increased stiffness strengthens unconfined edges, promotes better joint matching

Increased Density and Smoothness

- Compacting asphalt at its highest temperature helps maximize density and deliver smoother results

- Kinetic mixing action created by the angular plates helps increase the bond interface between the asphalt binder and aggregate while promoting thermal uniformity for improved compaction characteristics

- Increased in-place density can enable compaction to occur on a hotter surface shortening the compaction train

- Higher stiffness values can lead to better longitudinal edge profiles and higher joint densities due to less lateral movement of the mix when being compacted

Product Brochures