Conditional Content 1

Conditional Content 2

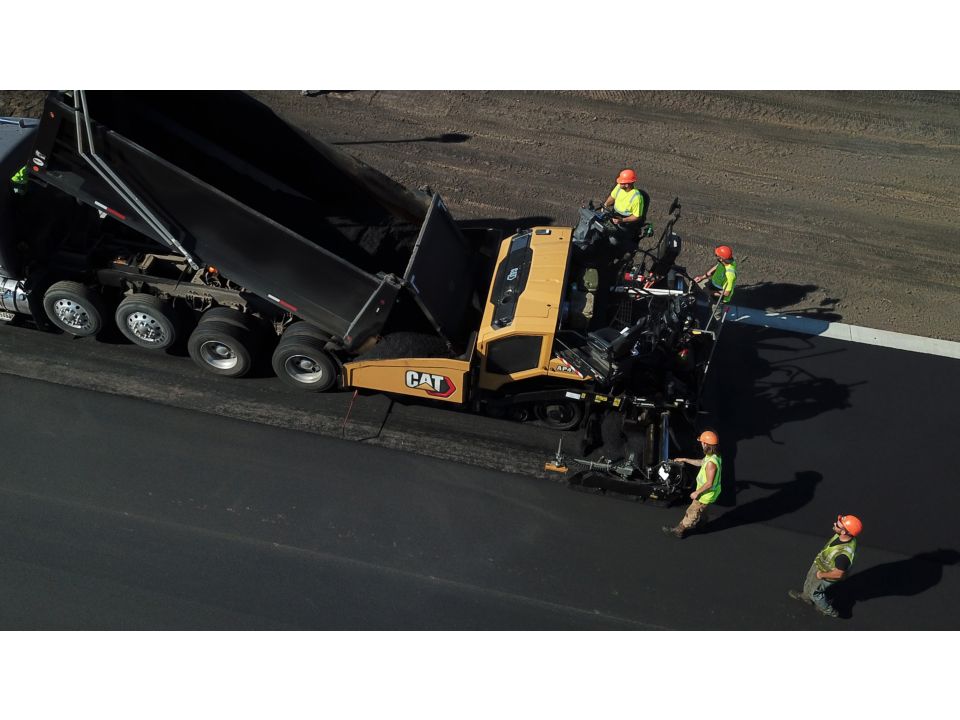

AP455

AP455

Track-equipped pavers offer superior traction for challenging projects that have poor underfoot conditions or the need to push large haul units up steep grades. Mobil-Trac™ undercarriage systems provide increased mobility and smooth, quiet operation. Some models are available with steel tracks for dependable use and low-cost maintenance. All models feature material feed systems with individual control of conveyors and augers designed to provide continuous, segregation-free material flow to the screed. The ventilation system draws fumes away from the conveyor tunnel as well as the auger chamber and redirects them away from the operator for a more comfortable working environment.

Book a Demo

Explore my deals

Specifications

Dimensions

-

Paving Range with SE47 FM2.4 m - 5.9 m (8' - 19' 6")

-

Paving Range with SE47 V2.4 m - 6.1 m (8' - 20')

-

Truck Entry Height22 in 567 mm

-

Operating Length19 ft 5.8 m

-

Operating Width10.75 ft 3.3 m

-

Overall Height10.75 ft 3.2 m

-

Transport Length18.1 ft 5.5 m

-

Transport Width8.5 ft 2.5 m

-

Transport Height8.6 ft 2.5 m

Engine

-

Engine Power (1)120 hp 90 kW

-

Engine Model (1)Cat C3.6

Operating Specifications

-

Maximum Throughput Capacity853 ton(US)/h 774 tonnes/hr

-

Maximum Paving Speed200 ft/min 61 m/min

-

Maximum Travel Speed7 mile/h 11 km/h

Service Refill Capacities

-

Fuel Tank53 gal (US) 200 l

-

DEF Tank5 gal (US) 19 l

-

Cooling System - Total6.3 gal (US) 24 l

-

Hydraulic Oil Tank32 gal (US) 121 l

-

Washdown Spray Tank8.5 gal (US) 32 l

Weights

-

Operating weight with SE47 FM31533 lb 14303 kg

-

Operating weight with SE47 V31292 lb 14194 kg

-

Shipping Weight - Paver Only24837 lb 11266 kg

Benefits

Compact Size, Big Opportunities

- The compact size and small footprint simplify maneuverability in tight spaces for efficient work in urban-type applications

- Tight 90 turning capability enables the paver to rotate and cover tracks on a return paving pass

- Standard paving range utilizing the SE47 V screed is 2.4 m - 4.7 m (8' - 15'6") with a maximum width of 6.1 m (20')

- Standard paving range utilizing the SE47 FM screed is 2.4 m - 4.7 m (8' - 15'6") with a maximum width of 5.9 m (19' 6")

- Paving depths up to 250 mm (10") supports aggregate paving applications

Transport Made Easy

- Paver and screed combination weight of 14.3 mt (31,500 lb) enables easy transport on a variety of trailer types

- Length of less than 5.5 m (18' 1") and width of 2.6 m (8' 6") accommodates machine transport without special permits

- The front-loading angle of 18 degreesand high front bumper clearance reduces the need for additional blocking when loading onto various trailer designs

- Front, middle, and rear tie-down locations make securing the paver efficient for quick travel to the next job site

Exceptional Mobility

- Mobil-trac ™ undercarriage provides exceptional mobility, outstanding traction, and fast travel speeds for unmatched maneuverability around the job site

- Counter-rotating tracks provide excellent maneuverability in tight quarters

- Self-tensioning accumulators, center guide blocks, and rugged internal belt cables help ensure durability

- Rubber-coated components help shed asphalt and prevent accumulation

- Efficient track plow design pushes material away from the tracks and helps eliminate cold patches caused by track compression

Smooth Material Flow

- Low truck entry height and short front apron enhances material flow while simplifying clean-out

- Feeder system design with 355 mm (14") diameter augers provides consistent material flow across the screed for efficient flow at both narrow and wide paving widths

- Confined auger chamber keeps material moving and helps eliminate stagnate patches

- Independent control of each material feed sensor when utilizing a cut-off shoe, simply turn off the sensor for manual proportional feed system control

More Comfort

- Ventilation system draws fumes from the auger chamber and redirects them away from the operator for a more comfortable working environment

- Single sliding console enables operation from either side of the machine

- Dual independent seats swing out 40 degrees beyond the platform for good visibility to curbs and obstacles

- Optimized height and integrated exhaust provide unobstructed visibility around the machine

- Optional screed and paver mounted umbrellas offer protection from direct sun

- Heated seat option delivers comfort in cool weather conditions

- High visibility 76 mm (3") seat belt helps with crew safety compliance

Easy Viewing Displays

- High-definition, touchscreen displays with adjustable brightness control for all types of lighting conditions, including direct sunlight

- New touch screen operating display with simplified menu structures, intuitive graphics, and short-cut keys help simplify machine adjustments

- Single-touch functions from the main screen include screed heat, wash-down system, vibratory activation, ventilation system, and the accessory panel

- Operating displays can be tailored to specific language requirements with multiple options available

- Wash-down system includes level indication

Screeds that Deliver Quality

- SE-Series screeds deliver excellent ride, density, and mat texture while providing superior adjustment capabilities

- Screeds with front-mounted extenders and rear-mounted extenders are available

- Cat Grade Control or Basic Grade Control options available

Low Owning and Operating Costs

- Durable Cat C3.6 engine provides 90 kW (120 hp) of power and meets U.S. EPA Tier 4 Final and EU Stage V emissions

- Exclusive Eco-mode and Automatic Engine Speed Control reduce fuel consumption and lowers sound levels for better job site communication

- Conveyor bed plates and chain guards are designed to minimize labor requirements and lower replacement costs

- Maintenance-free high torque motors for the auger and conveyor drive systems reduce service requirements

Product Link™ Elite

- Make timely, fact-based decisions to maximize efficiency, improve productivity, and lower owning and operating costs

- Easily track location, machine hours, fuel usage, and idle time in real time

- Diagnostic codes are made available through online web applications

- Remote flash for easy software updates

- Scheduled maintenance and SOS notification

- Remote disable deactivates the engine for enhanced security

Service and Repair Kits

- Paver and screed service and repair kits include all the parts necessary to complete specific repairs

- Cat genuine parts are manufactured to precise specifications and designed for optimal performane and maximum uptime

- Repair kits are identified by a single part number to make ordering easy

- Select kits are available to be packaged as a kit by the dealer for over the counter purchases or through the dealer service shop

Sustainability

- The Cat® C3.6 engine is available in configurations that meet U.S. EPA Tier 4 Final emission standards.

- Cat U.S. EPA Tier 4 Final diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- The engine, fuel and hydraulic systems are equipped with ecology drains for easy servicing and to help prevent spillage.

- Cat Scheduled Oil Sampling (S•O•S?) Services helps reveal excessive wear, contaminated fluids or other “unseen” issues that can shorten component life. In many cases, you can extend oil and coolant change intervals by using fluid monitoring. Consult your Cat dealer or the machine’s operation and maintenance manual for more information.

- Cat Grade with Grade and Slope for Asphalt Pavers allows for accurate material planning to help reduce overages during the paving process and increase final project quality for a longer lasting road surface.

- Don’t waste fuel idling. Cat VisionLink® online fleet monitoring helps you manage idle time and reduce fuel burn and greenhouse gas emissions.

- VisionLink displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range.

Equipment Info

Operating Environment

Single sliding console

Technology

Product Link™ Elite 643 (cellular)

Powertrain

Cat C3.6, four-cylinder

Electrical System

1400 CCA battery

Material Delivery

Auger extensions, 0.15 m (6")

Service and Maintenance

Hydraulic oil, Cat HYDO Advanced

Safety

Alarm, back-up

Product Brochures