Conditional Content 1

Conditional Content 2

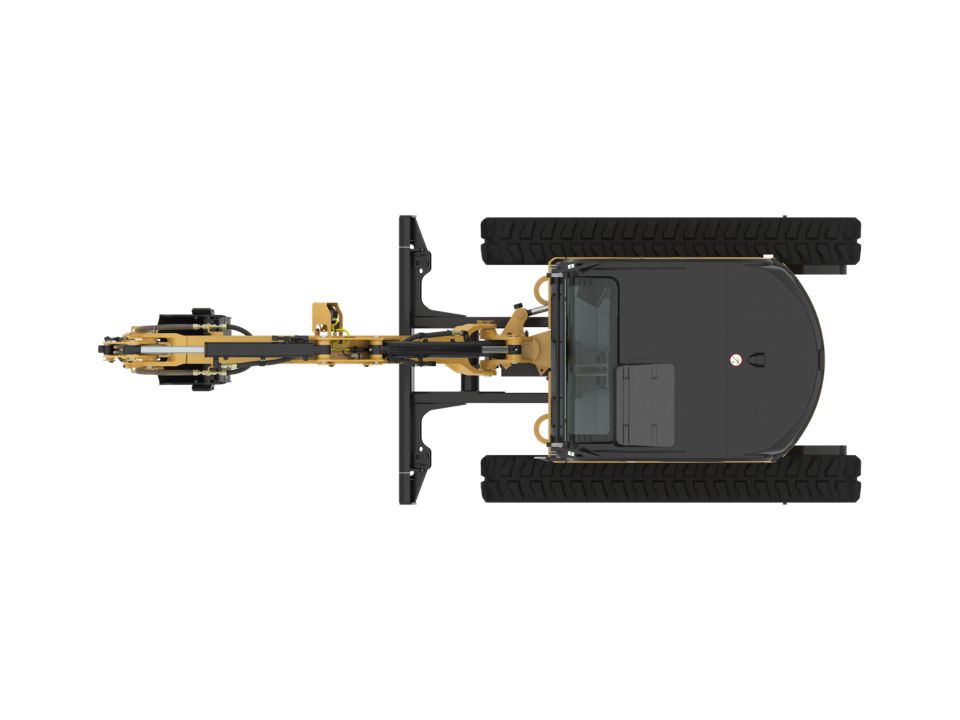

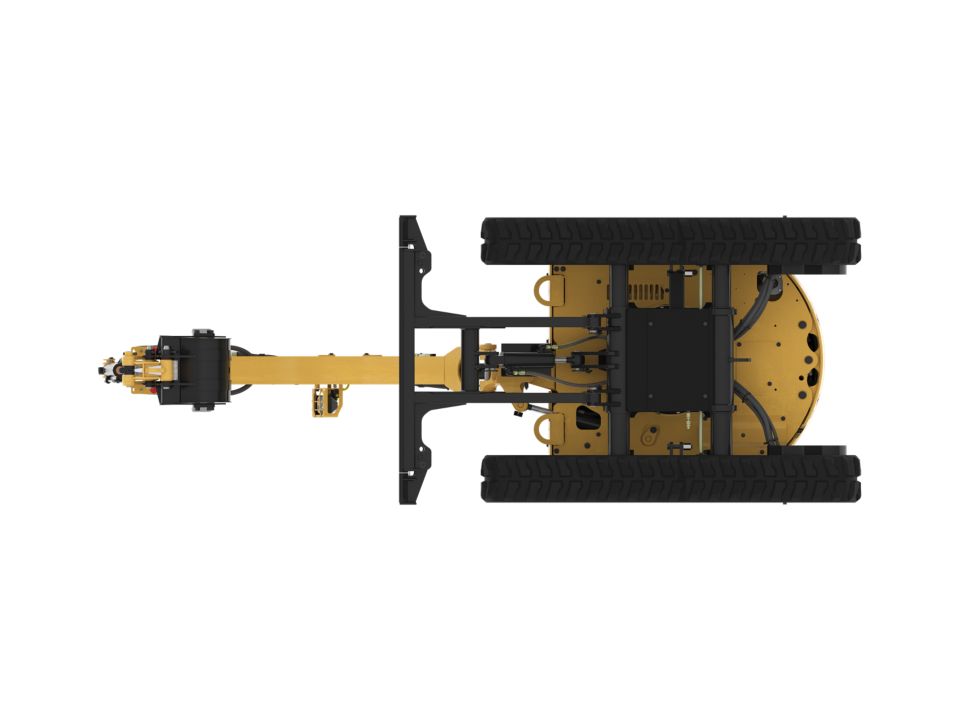

302 CR

302 CR

An extensive line of Cat® mini hydraulic excavators offers the performance to dig in and be productive on every job.

Book a Demo

Explore my deals

Specifications

Blade

-

Height8.9 in 225 mm

-

Width*42.9 in 1090 mm

-

Note*Expanded – 1400 mm (55 in)

Certification - Cab and Canopy

-

Top GuardISO 10262:1998 (Level I)

-

Roll Over Protective Structure (ROPS)ISO 12117-2:2008

-

Tip Over Protective Structure (TOPS)ISO 12117:1997

Dimensions - Long Stick

-

Dig Depth101.2 in 2570 mm

-

Track Belt/Shoe Width9.8 in 250 mm

-

Tail Swing29.5 in 750 mm

-

Maximum Dump Clearance103.9 in 2640 mm

-

Vertical Wall76.4 in 1940 mm

-

Boom In Reach65.4 in 1660 mm

-

O/A Shipping Height90.6 in 2300 mm

-

Maximum Blade Depth11.6 in 295 mm

-

Track Width - Retracted42.9 in 1090 mm

-

Stick Length45.7 in 1160 mm

-

Boom Height - Shipping Position40.2 in 1020 mm

-

Maximum Reach168.1 in 4270 mm

-

Swing Bearing - Height17.4 in 442 mm

-

Boom Swing - Right50 ° 50 °

-

Track Width - Expanded55.12 in 1400 mm

-

Boom Swing - Left65 ° 65 °

-

Maximum Dig Height142.5 in 3620 mm

-

O/A Undercarriage Length72.8 in 1850 mm

-

Maximum Blade Height11.2 in 285 mm

-

Maximum Reach - Ground Level165.7 in 4210 mm

-

Overall Shipping Length*152.8 in 3880 mm

-

Minimum Ground Clearance Below Undercarriage5.9 in 150 mm

-

Note*Overall Shipping Length depends on blade position during shipment.

Dimensions - Standard Stick

-

Dig Depth93.3 in 2370 mm

-

Maximum Dig Height139.8 in 3550 mm

-

Track Belt/Shoe Width9.8 in 250 mm

-

Tail Swing29.5 in 750 mm

-

Boom Height - Shipping Position42.1 in 1070 mm

-

O/A Shipping Height90.6 in 2300 mm

-

Overall Shipping Length*153.5 in 3900 mm

-

Maximum Blade Height11.2 in 285 mm

-

Maximum Reach161.8 in 4110 mm

-

Track Width - Expanded55.12 in 1400 mm

-

Track Width - Retracted42.9 in 1090 mm

-

Boom Swing - Right50 ° 50 °

-

O/A Undercarriage Length72.8 in 1850 mm

-

Maximum Reach - Ground Level159.1 in 4040 mm

-

Swing Bearing - Height17.4 in 442 mm

-

Stick Length37.8 in 960 mm

-

Boom Swing - Left65 ° 65 °

-

Boom In Reach65.4 in 1660 mm

-

Maximum Dump Clearance100.8 in 2560 mm

-

Minimum Ground Clearance Below Undercarriage5.9 in 150 mm

-

Maximum Blade Depth11.6 in 295 mm

-

Note*Overall Shipping Length depends on blade position during shipment.

-

Vertical Wall72.8 in 1850 mm

Engine

-

Net Power21 hp 15.7 kW

-

Engine ModelC1.1

-

Note (2)Net power advertised is the power available at the flywheel when the engine is at rated speed and rated power when the engine is installed with the factory configured fan, air intake system, exhaust system, and alternator with a minimum alternator load.

-

Bore3 in 77 mm

-

Stroke3.2 in 81 mm

-

EmissionsMeets U.S. EPA Tier 4 Final and EU Stage V emission standards.

-

Displacement69 in³ 1.1 l

-

Note (1)Engine power is tested per ISO 14396:2002.

-

NoteNet power is tested per ISO 9249:2007 and 80/1269/EEC.

-

Net Power - 2,400 rpm - ISO 9249, 80/1269/EEC21 hp 15.7 kW

-

Gross Power - SAE J1995:201421.6 hp 16.1 kW

Hydraulic System

-

Pump Flow at 2,400 rpm17.4 gal/min 66 l/min

-

Digging Force - Stick - Standard2540.3 lbf 11.3 kN

-

Auxiliary Circuit - Primary - Flow8.7 gal/min 33 l/min

-

Digging Force - Bucket4406.3 lbf 19.6 kN

-

Auxiliary Circuit - Secondary - Pressure3553.4 psi 245 bar

-

Operating Pressure - Travel3553.4 psi 245 bar

-

Operating Pressure - Equipment3553.4 psi 245 bar

-

Operating Pressure - Swing2132.1 psi 147 bar

-

Digging Force - Stick - Long2203.1 lbf 9.8 kN

-

TypeLoad Sensing Hydraulics with Variable Displacement Piston Pump

-

Auxiliary Circuit - Primary - Pressure3553.4 psi 245 bar

-

Auxiliary Circuit - Secondary - Flow3.7 gal/min 14 l/min

Service Refill Capacities

-

Cooling System1 gal (US) 3.9 l

-

Hydraulic Tank4.8 gal (US) 18 l

-

Hydraulic System6.9 gal (US) 26 l

-

Engine Oil1.2 gal (US) 4.4 l

-

Fuel Tank6.9 gal (US) 26 l

Sound

-

Average Exterior Sound Pressure (ISO 6395:2008)93 dB(A) 93 dB(A)

-

NoteEuropean Union Directive “2000/14/EC”

-

Operator Sound Pressure (ISO 6396:2008)73 dB(A) 73 dB(A)

Sustainability

-

Recyclability95%

Swing System

-

Machine Swing Speed9.8 r/min 9.8 r/min

Travel System

-

Travel Speed - High2.7 mile/h 4.4 km/h

-

Travel Speed - Low1.8 mile/h 2.9 km/h

-

Maximum Traction Force - Low Speed4496.2 lbf 20 kN

-

Maximum Traction Force - High Speed2967.5 lbf 13.2 kN

-

Gradeability - Maximum30 degrees

-

Ground Pressure - Maximum Weight3.9 psi 26.8 kPa

-

Ground Pressure - Minimum Weight3.4 psi 23.7 kPa

Weight Increase from Minimum Configuration

-

Steel Tracks132 lb 60 kg

-

Long Stick18 lb 8 kg

-

Expandable Undercarriage212 lb 96 kg

Weights

-

Operating Weight4987 lb 2262 kg

-

Maximum Operating Weight with Cab**4987 lb 2262 kg

-

Minimum Operating Weight with Canopy*4229 lb 1918 kg

-

Note (2)**Maximum Weight is based on steel tracks, operator, expandable undercarriage and full fuel tank.

-

Maximum Operating Weight with Canopy**4588 lb 2081 kg

-

Minimum Operating Weight with Cab*4535 lb 2057 kW

-

Note (1)*Minimum Weight is based on rubber tracks, operator, fixed undercarriage and full fuel tank.

-

Note (3)***CE Plate Weight is based on the most common EU configuration. Includes 75 kg (165 lb) operator and full fuel tank and excludes bucket.

-

EU: CE Plate Weight with Cab***4718 lb 2140 kg

-

EU: CE Plate Weight with Canopy***4508 lb 2045 kg

Benefits

ALL DAY COMFORT

- Choose either a canopy or a sealed and pressurized cab equipped with air conditioning, adjustable wrist rests, and a suspension seat option to help keep you working comfortably all day long.

EASY TO OPERATE

- Controls are easy to use and the intuitive Next Generation LCD monitor provides easy to read machine information.

STICK STEER TRAVEL MODE

- Moving around the job site is even easier with the Cat Stick Steer option. Easily switch from traditional travel controls with levers and pedals to joystick controls with a push of a button. The benefit of less effort and improved control is in your hands!

BIG PERFORMANCE IN A COMPACT DESIGN

- Strong lift and dig performance helps you get the job done faster. The compact radius design and retractable undercarriage lets you access and work in the tightest areas. Dig-to-blade and dozer float features allow for easy clean up.

SAFETY ON THE JOB SITE

- Your safety is our top priority. The Cat mini excavator is designed to help keep you safe on the job. Courtesy work lights and a fluorescent retractable seat belt are just a couple of the safety features we’ve built into the machine.

SIMPLE SERVICE FOR LESS DOWNTIME

- Maintenance is quick and easy on the Cat mini excavator. Routine check points are easy to access at ground level through the side doors. The unique tilt up cab lets you reach additional service areas when needed.

LOWER OPERATING COSTS

- Equipped with features such as auto idle, auto engine shutdown, and efficient hydraulics with a variable displacement pump, the Cat mini excavator was designed with reducing your operating costs in mind.

SUSTAINABILITY

- The Cat® C1.1 engine meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) * or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Auto Idle helps reduce unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- Engine Idle Shutdown Timer reduces fuel burn, greenhouse gas emissions and unnecessary idle time by shutting down the machine after a pre-set idling period.

- Cruise control helps you maintain a constant speed as you travel across your jobsite saving fuel and reducing greenhouse gas emissions.

- The Cat® Seat Belt Reminder provides audible and visual warnings to remind operators to buckle up during machine operation. The easy-to-install system is compatible with all equipment brands to help ensure operator safety.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.(if equipped)

- Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency by allowing your Cat dealer to virtually test the machine while working. Once a problem is identified, a technician can fix it the first time, saving time and money.(if equipped)

Equipment Info

ENGINE

Cat C1.1 Engine (U.S. EPA Tier 4 Final/EU Stage V)

HYDRAULICS

Smart Tech Electronic Pump

OPERATOR ENVIRONMENT

Tilt-up Canopy or Tilt-Up Cab

UNDERCARRIAGE

Expandable Undercarriage

BOOM, STICK AND LINKAGES

One Piece Boom (1850 mm/73 in)

ELECTRICAL

12 Volt Battery