Conditional Content 1

Conditional Content 2

CP11 GC (Tier 4F / EU Stage V)

CP11 GC (Tier 4F / EU Stage V)

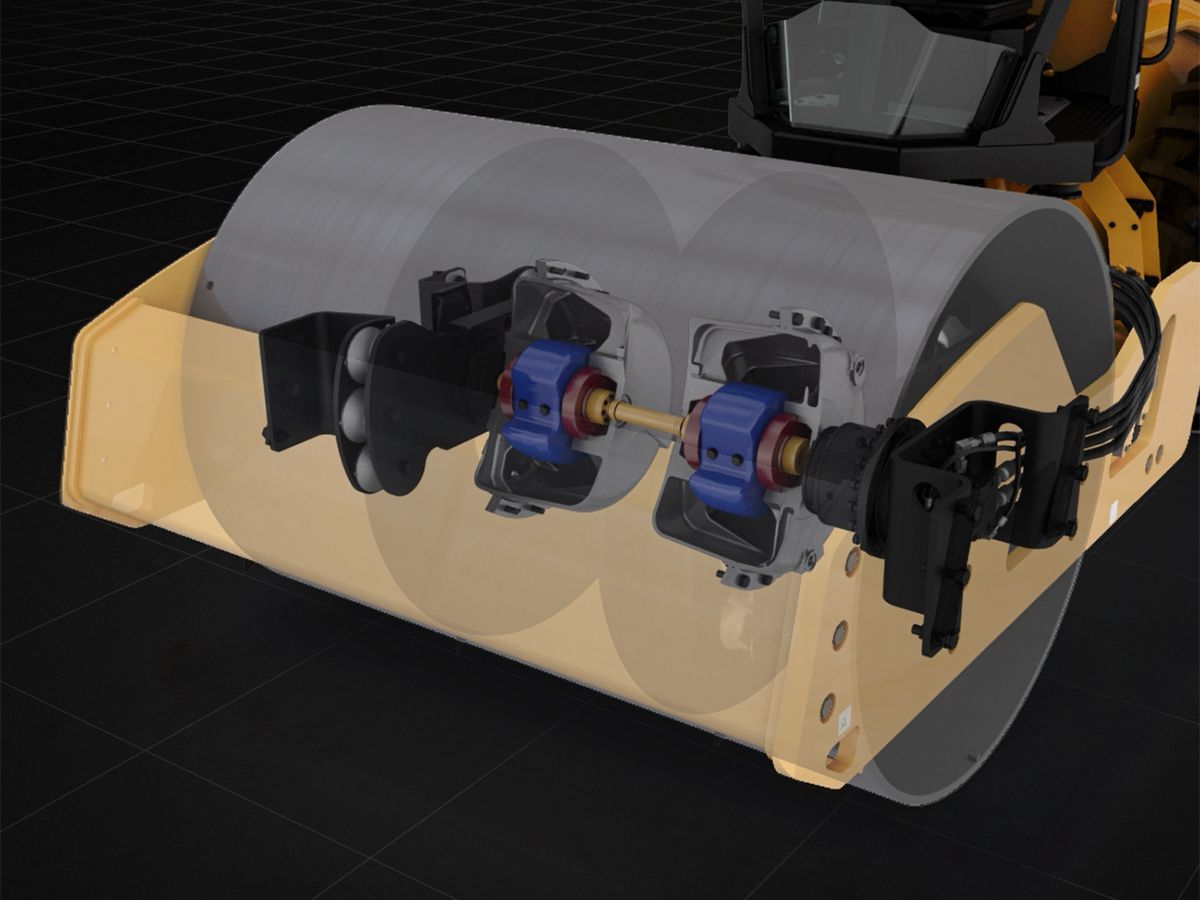

Smooth drum compactors produce consistently reliable results when compacting semi-cohesive and granular materials. With operating weights up to almost 19 metric tons, there is a Cat Soil Compactor sized to meet the most demanding production and density requirements.Padfoot drum compactors produce consistently reliable results when compacting semi-cohesive and cohesive materials. Pads are tapered and penetrate deeply into the soil to build strength from the bottom up. Small pad face area concentrates force to deliver the highest compaction energy so production goals are met with fewer units and less fuel consumed.All dual-amplitude models feature an exclusive Cat eccentric weight design that assures positive amplitude selection while preventing contamination of the weight shaft bearing lubrication.

Book a Demo

Explore my deals

Specifications

Dimensions

-

Compaction Width84 in 2134 mm

-

Overall Length18.7 ft 5.7 m

-

Overall Width7.5 ft 2.3 m

-

Maximum Height9.8 ft 3 m

-

Drum Diameter - Over Pads60.9 in 1549 mm

-

Wheel Base9.8 ft 3 m

Engine

-

Gross Power122.9 hp 91.7 kW

-

Engine Power - ISO 14396121 hp 90 kW

-

Net Power - ISO 9249112.2 hp 83.7 kW

-

Net Power - SAE J1349:2011111.2 hp 82.9 kW

-

Note (1)Net power advertised is the power available at the engine flywheel when equipped with a fan at maximum speed, air cleaner, clean emissions module, and alternator.

-

Engine ModelCat® C3.6

-

EmissionsU.S. EPA Tier 4 Final, EU Stage V, Korea Stage V

-

Stroke4.7 in 120 mm

-

Bore3.9 in 98 mm

Operating Specifications

-

Ground Clearance20.3 in 516 mm

-

Curb Clearance19.5 in 496 mm

-

Turning Radius - Inside Drum Edge12.7 ft 3.9 m

-

Travel Speed - Maximum6.8 mile/h 11 km/h

Service Refill Capacities

-

Fuel Tank Capacity56.3 gal (US) 213 l

-

DEF Tank5 gal (US) 19 l

-

Cooling System4.9 gal (US) 18.5 l

-

Engine Oil - With Filter3.1 gal (US) 11.6 l

-

Eccentric Weight Housings (combined)6.9 gal (US) 26 l

-

Axle and Final Drives2.6 gal (US) 10 l

-

Hydraulic Tank6.1 gal (US) 23 l

Sustainability

-

Recyclability97%

Vibratory System

-

Nominal Amplitude - High0.071 in 1.8 mm

-

Nominal Amplitude - Low0.035 in 0.89 mm

-

Centrifugal Force - Maximum55932 lb 249 kN

-

Centrifugal Force - Minimum33249 lb 148 kN

Weights

-

Operating Weight - With Cab25109 lb 11389 kg

-

Operating Weight - With ROPS/FOPS Canopy24769 lb 11235 kg

-

Weight - Drum with Cab14084 lb 6388 kg

-

Weight - Drum with ROPS/FOPS Canopy13988 lb 6345 kg

-

Note (1)Operating weights are approximate and consider full fluids and 75 kg (165 lb) operator. Cab weights include heat and air conditioning.

Benefits

Reliable Power

- The propel system is driven by a single pump design and is ideal for flat to moderate grades.

- Powered by a Cat® C3.6 engine that meets U.S. EPA Tier 4 Final, EU Stage V and Korea Stage V emission standards.

- Eco-mode limits engine RPM helping to reduce fuel consumption.

- Engine Idle Shutdown Timer reduces fuel burn and unnecessary idle time by shutting down the machine after a pre-set idling period.

Comfortable and Ergonomic Operator Station

- The ISO-mounted operator station and rubber floormats help reduce noise and vibration for comfort during operation.

- Easy to use controls are grouped by function and a large display informs operators of machine performance.

- The seat, armrest and steering column are adjustable for all-day comfort.

- Operators are protected from the elements by a standard equipped ROPS/FOPS canopy or an optional climate-controlled ROPS/FOPS cab with hinged glass windows.

- Cab configurations can be upgraded to a deluxe high back air-ride seat to enhance operator comfort.

Safety Features

- Angled steps, handrails, and an antiskid surface help provide stability during entry and exit of the operator station.

- Internal and external mirrors are available to provide the operator with a broad view of the jobsite.

- Enhance visibility with an optional rear vision camera with large color touchscreen display for more complete operator control and safety.

- Optional operator presence seat sensor and seat belt switch.

Excellent Compaction Performance

- The exclusive pod-style eccentric weight vibratory system is designed to provide high reliability, smooth performance and low noise levels with a 3-year, 3000-hour maintenance interval.

- High static linear loads and amplitudes.

- The optional Traction Control system helps improve traction in soft underfoot conditions such as sand or loose material.

- The Auto-vibe function helps operators easily maintain consistent, high-quality compaction.

- The drum features unique, tapered, oval-faced pads engineered to penetrate deeper and deliver higher weight concentration to maximize compactive effort. Also available in a square pad design.

Enhance Quality and Productivity with Technology

- Optional Cat Compact technologies help you consistently meet compaction targets faster, more uniformly, and in fewer passes – saving on fuel and reducing rework and material costs.

- Exclusive Machine Drive Power (MDP) is an energy-based measurement and can be used on all soil types in either static or vibratory mode.

Virtually Maintenance Free

- The articulated hitch with sealed-for-life bearings does not require routine maintenance.

- Ground-level access to all maintenance points for easy service and fluid sampling.

- Monitor fluid conditions with regular sampling to help extend change intervals up to 500 hours engine oil, 3000 hours eccentric housing and hydraulic oil, and 12000 hours coolant.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- VisionLink® takes the guesswork out of managing your entire fleet–regardless of size or equipment manufacturer*–by providing maintenance needs, machine hours, location, fuel usage, idle time, diagnostic codes, and more through interactive dashboards on your mobile device or desktop, helping you make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite.

- Remote Flash allows you to update onboard software without a technician being present, allowing you to initiate software updates when convenient, increasing your overall operating efficiency**

- Remote Troubleshoot allows your Cat dealer to perform diagnostic testing on your connected machine remotely**

* Data field availability can vary by equipment manufacturer and is provided through an application programming interface (API).

** Must be within cell range coverage.

Sustainability

- The Cat C3.6 is available in configurations that meet U.S. EPA Tier 4 Final, EU Stage V and Korea Stage V emission standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels* up to: 20% biodiesel FAME (fatty acid methyl ester) or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels Refer to guidelines for successful application. Please consult your Cat dealer or "Caterpillar Machine Fluids Recommendations" (SEBU6250) for details.

*Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. - Auto engine idle shutdown helps reduce unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- A well-trained operator is worth the investment. Skilled operators benefit your bottom line by maximizing productivity, avoiding costly downtime, and maintaining jobsite safety - which can help to improve fuel efficiency and reduce greenhouse gas emissions.

- Extended maintenance intervals not only reduce downtime but can decrease the amount of fluid and filters that are replaced over the life of the machine. Extend change intervals up to 500 hours engine oil, 3000 hours eccentric housing and hydraulic oil, and 12000 hours coolant.

- Performance and safety can be augmented with standard and optional cameras that are viewed on in-cab displays.

- Cat Compact technologies help you consistently meet compaction targets faster, more uniformly, and in fewer passes - saving on fuel and reducing rework and material costs.

- Cat Scheduled Oil Sampling (S•O•S?) Services helps reveal excessive wear, contaminated fluids or other "unseen" issues that can shorten component life. In many cases, you can extend oil and coolant change intervals by using fluid monitoring. Consult your Cat dealer or the machine's operation and maintenance manual for more information.

Equipment Info

NOTE

Standard and optional equipment may vary. Consult your Cat dealer for details.

OPERATOR ENVIRONMENT

ROPS/FOPS Canopy with Handrails, Floor Mat, Interior Rear View Mirror

VIBRATORY SYSTEM

Padfoot Drum - Oval or Square Pads

TECHNOLOGY SOLUTIONS

VisionLink®

POWERTRAIN

Cat® C3.6 Engine

ELECTRICAL

12-Volt Electrical System

OTHER

Scheduled Oil Sampling S·O·S? Ports: Engine Oil, Hydraulic Oil, and Coolant