Conditional Content 1

Conditional Content 2

CB2.5 GC

CB2.5 GC

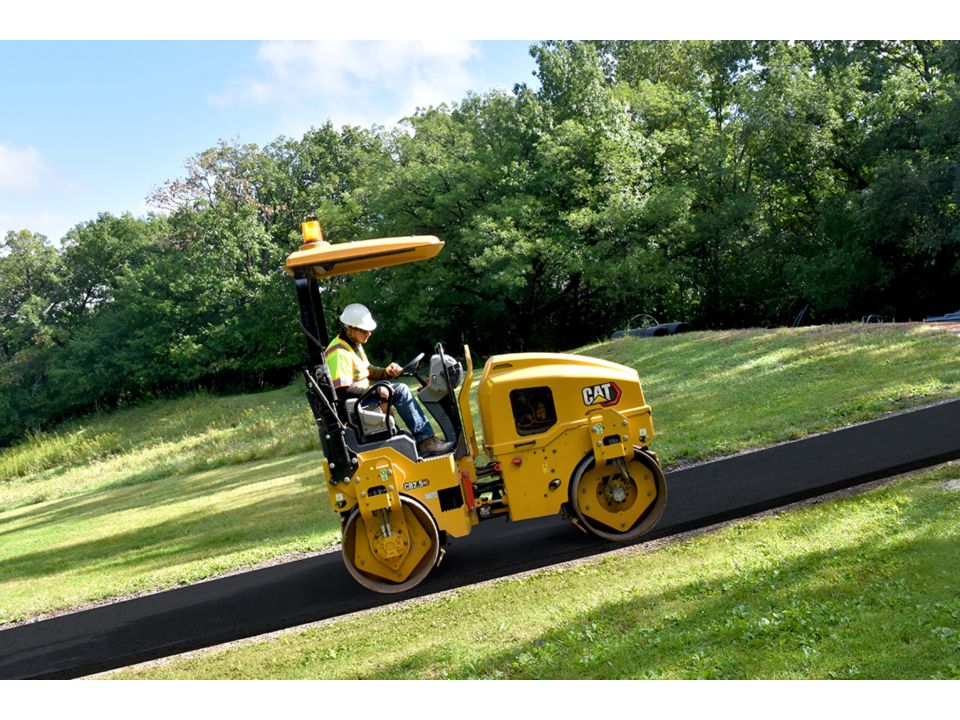

Get it dense and keep it smooth. Cat Tandem Vibratory Rollers do that and more. Caterpillar offers a vibratory system for every application. Most models have high frequency combined with low amplitude that match high paving speed on thin lifts as well as low frequency with high amplitude that match low paving speed on thick lifts of stiff material. As stand-alone units or as complements to high production tandem rollers, Cat Utility Rollers set the standards for versatility and reliability. A wide range of drum widths lets you precisely match the machine to the job requirements—whether it's a narrow shoulder, a patching project, a parking lot or a bicycle path. Vibratory systems are characterized by high frequency for fast working speed and high compaction energy for getting density in the fewest passes.

Book a Demo

Explore my deals

Specifications

Dimensions

-

Compaction Width39.4 in 1000 mm

-

Wheel Base70.9 in 1800 mm

-

Overall Width43.8 in 1112 mm

-

Drum Width39.4 in 1000 mm

-

Height - ROPS102.2 in 2595 mm

-

Overall Length102.2 in 2596 mm

-

Drum Diameter28.3 in 720 mm

Engine

-

Engine Power (1)24.7 hp 18.4 kW

-

Engine ModelC1.7T

Operating Specifications

-

Travel Speed - Maximum5.8 mile/h 9.4 km/h

-

Static Linear Load66.2 lb/in 11.85 kg/cm

-

Turning Radius - Outside Drum Edge143.3 in 3640 mm

-

Drum Offset2 in 50 mm

-

Curb Clearance17.8 in 453 mm

-

Ground Clearance11.2 in 285 mm

-

Turning Radius - Inside Drum Edge103.9 in 2640 mm

Service Refill Capacities

-

Water Spray Tank Capacity52.8 gal (US) 200 l

-

Fuel Tank Capacity14.37 gal (US) 55 l

Vibratory System

-

Nominal Amplitude - High0.02 in 0.51 mm

-

Centrifugal Force - Maximum5885.3 lb 26.2 kN

-

Frequency62 Hz 3720 VPM

Weights

-

Standard Operating Weight with ROPS5546 lb 2521 kg

-

Maximum Operating Weight with ROPS2607 lb 1185 kg

-

Maximum Weight at Front Drum2607 lb 1185 kg

-

Maximum Weight at Rear Drum2939 lb 1336 kg

Benefits

Simple to Operate

- Convenient, dual-side access with large handrails and wide

- slip-resistant steps simplify ingress/egress

- Operating console includes gauges for fuel level, water tank level, hour meter, engine coolant temperature as well as warning light indicators to help keep the operator informed

- Durable rocker style switches provide easy activation for engine speed, vibratory drum selection, parking brake, lights, and the optional warning beacon

- Engine speed is controlled with a momentary selection switch for low, mid-range, and high speed settings

- Optional fore/aft and side to side seat adjustments combine with dual propel levers to enable good visibility to either side of the machine

Proven Powertrain

- Efficient Cat® C1.7T engine provides 18.4 kW (24.7 hp) of power (U.S. EPA Engine power is 17.8 kW (23.8 hp)?.

- Auto-warmup feature is designed to prevent vibratory system activation and high engine idle speed until the hydraulic system reaches 10º C (50º F)

- Auto-idle shutdown activates after the factory set default of 30 minutes, shutdown time can be adjusted with Cat Electronic Technician (Cat ET)?

- Maximum gradeability occurs when operated with the mid-range engine speed of 1800 rpm selected, while maximum travel speed occurs at the high engine speed of 2200 rpm

- Optional traction control is designed to minimize drum slips and enhance gradebility

Compaction Performance

- Two vibratory frequencies of 50 Hz (3000 vpm) and 62 Hz (3720 vpm) correspond with engine speeds of 1800 rpm and 2200 rpm to provide working speed versatility

- Front only, rear only, or both drum vibratory capablities help operators conform to a variety of conditions

- Automatic vibratory control offers ramp in, ramp out adjustment, configurable through Cat ET

- Optional Compaction Meter Value (CMV) is designd to keep the operator informed of compaction performance and provide quality control measures

- Single point lift option and robust hitch design provides transport options as well as expanded application versatility for trench work

- Ballast options mounted to the drum supports provide flexibility that increases static linear load for addtional compaction performance

Keep the Drums Clean

- Pressurized water spray system with intermittent settings is designed to help operators match conditions for efficient performance

- Triple filtration helps prevent clogs with filters located at the fill point, water pump, and spray nozzles

- The automatic on/off feature deactivates the water spray system when the propel lever moves to neutral and activates the system when the propel lever moves from neutral

- Adjustable folding or fixed design drum scraper options are available

- The integrated freeze protection kit (optional) provides protection in cold temperatures when the machine is not in use

Service and Maintenance

- VisionLink® is a cloud-based software application that provides data to desktop or mobile devices, taking the guesswork out of fleet management with key insights to maximize performance – regardless of fleet size or equipment manufacturer?

- Cat Electronic Technician (Cat ET) capability provides service and trouble-shooting simplification

- Oil change interval of 500 hours is designed to limit downtime and reduce routine maintenance costs

- External fuel fill with lockable cap offers easy access, while providing security

- LED lighting delivers good job site illumination while conserving energy

- Uptime kits and Customer Value Agreements (CVA) are designed to limit downtime

Safety

- An operator presence switch located in the seat is designed to prevent machine operation when not activated

- The seat is equipped with a standard 75 mm (3"), high-visibility, seatbelt that is designed to simplify in-use recognition

- Slip resistant steps and platform make it easier for operator ingress/egress

- Quick-connect harness supports easy installation and removal of the warning beacon

Sustainability

- The Cat® C1.7T engine meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester)** or 100% renewable diesel, HVO (hydrogenated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Auto engine idle shutdown helps reduce unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- A well-trained operator is worth the investment. Skilled operators benefit your bottom line by maximizing productivity, avoiding costly downtime, and maintaining jobsite safety – which can help to improve fuel efficiency and reduce greenhouse gas emissions.

- Extended maintenance intervals not only reduce downtime but can decrease the amount of fluid and filters that are replaced over the life of the machine. The hydraulic oil can be replaced every 3000 hours, eccentric housing oil can be replaced every 3000 hours, and engine oil changes can be 500 hours.

- Cat Compact technologies help you consistently meet compaction targets faster, more uniformly, and in fewer passes - saving on fuel and reducing rework and material costs.

- Cat Scheduled Oil Sampling (S•O•S?) Services helps reveal excessive wear, contaminated fluids or other “unseen” issues that can shorten component life. In many cases, you can extend oil and coolant change intervals by using fluid monitoring. Consult your Cat dealer or the machine's operation and maintenance manual for more information.

- Remote Flash for engines helps to minimize downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

- Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency by allowing your Cat dealer to virtually test the machine while working. Once a problem is identified, a technician can fix it the first time, saving time and money.

Equipment Info

OPERATOR ENVIRONMENT

Adjustable Suspension Seat with Operator Presense Switch

COMPACTON SYSTEM

Folding Scrapers

POWERTRAIN

Auto Engine Off and Auto Warmup

TECHNOLOGY

Telematics

ELECTRICAL

LED Working Lights

OTHER

Vandal Protection - lockable hood, fuel fill, and controls cover

Product Brochures